woven multifilament polypropylene geotextiles - high strength

1.increases construction project life, 2.filtration,separation,reinforcement,erosion control, 3.corrosion resistance,perviousnes - details see: https://www.buildingsupplieshub.com/woven-multifilament-polypropylene-geotextiles-10059303

| Type: Geotextiles | Place of Origin: Zhejiang China (Mainland) | Brand Name: Shenlian | Geotextile Type: Woven Geotextiles |

| Model Number: high strength | color: white | Feature: high permeability |

Brief introduction:

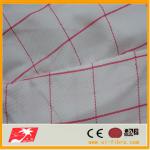

Polypropylene multifilament yarns are woven into a stable network.A woven geotextile retain its relative structure during handling,placement and long time service. As needed, geotextile material shall be added stabilizers to make the filaments resistant to ultraviolet light,oxidation and heat. Reducing civil engineering overall costs increases construction project life filtration separation reinforcement,erosion control high strength,low elongation corrosion resistance perviousness easy transportation dimensional stabilization speed construction cost efficiency

Polypropylene Woven Geotextile

Material: Polypropylene

Material: Polypropylene

Color: white,other colors available

Width:1.06-3.7M

Weight: Polypropylene 200gsm-1300gsm

Width:1.06-3.7M

Weight: Polypropylene 200gsm-1300gsm

Tensile strength: PP 40KN/M-400KN/M

permeability:0.01-0.8S-1

Pore size: 0.06-0.7mm

Elongation: Polypropylene <35%

Elongation: Polypropylene <35%

interweave method:plain, twill etc.

Benefits:filtration,separation,reinforcement,erosion control

Benefits:filtration,separation,reinforcement,erosion control

Civil and environmental applications: including highways, port facilities, reservoir, transport construction,

waste and chemical management, subgrade engineering, coastal protection works, peninsula shoal

engineering, subsurface drainage ,pile jacketing etc..

| Physical properties | Test method | Unit | Typical Value | |||||||||||

| Material | Polypropylene/PP | |||||||||||||

| Unit Weight | ASTM D 5261 | g/m2 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1300 | |||

| Color | White | |||||||||||||

| Mechanical properties | ||||||||||||||

| Tensile Strength at break MD | ASTM D 4595 | KN/M >= | 50 | 75 | 100 | 130 | 160 | 180 | 200 | 230 | 360 | |||

| Tensile Strength at break CD | ASTM D 4595 | KN/M >= | 35 | 52 | 70 | 90 | 112 | 126 | 140 | 160 | 280 | |||

| Elongation at break MD | ASTM D 4595 | % <= | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | |||

| Elongation at break CD | ASTM D 4595 | % <= | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |||

| CBR Puncture Strength | ASTM D 6241 | KN | 4 | 6.9 | 10.5 | 14 | 18 | 20.5 | 23 | 24 | 28 | |||

| Tear Strength | ASTM D 4533 | KN | 0.6 | 1 | 1.3 | 1.55 | 1.9 | 2 | 2.2 | 2.3 | 3.2 | |||

| Hydraulic Properties | ||||||||||||||

| Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||||||

| Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | |||||||||||

Width: max 3.8m, standard 3.6m. Other colors available. | ||||||||||||||

| Packaging Detail:rolled with cardboard core, fold |

| Delivery Detail:within 20 days |