woven Geotextile polymer geotextile - 100g--800g

woven Geotextile polymer geotextile, 1.Resist plant root, 2.High machine strength, 3.Fast construction, 4.timely delivery - details see: https://www.buildingsupplieshub.com/woven-geotextile-polymer-geotextile-10059080

| Type: Geotextiles,Geomembranes | Place of Origin: Shandong China (Mainland) | Model Number: 100g--800g | color: white |

| width: 5.7m( fit for container) | length: 30m, 40m, 50m | Material: HDPE, LDPE, PVC, EVA |

woven Geotextile polymer geotextile

Product Introduction

Geotextile has superior quality of soaking, filtering and endurance. It can widely apply in projects in projects such as railway, road, sport museum, disk, construction tunnel, coastal short line, reclamation and environmental protection. There are mainly short fiber knitting nontextile geotextile and crack textile geotextile.

Product Feature

- Geocloth can make the water flow easily, and form a drainage channel in the soil, and then make the liquid and gas out of the soil.

- Make use of its pulling resistance and deformation resistance that can strength the soil to reinforce the stability of the construction structure and improve the soil’s quality.

- Make the focus proliferate, deliver and decompose efficiently and prevent the soil from destruction from outside factor.

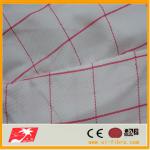

- Prevent the top and bottom layer’s gravel, soil and concrete from mixer.

- The mesh cannot be plugged easily – for the strain and moving quality of the network that formed by the antitype fiber.

- High soaking quality—at the pressure of soil, it also can keep good soaking quality.

- Corrosion resistant – using the polypropylene and polyester as raw material, it can resist the sour and aid, erosion, boring and oxidation.

- The construction is easy; the weight is light, convenient for using, and it making construction easy.

Technical Parameter

| Number | Item/indicator/specification | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remark |

| 1 | The quality of per area, deviation, % | 8 | 8 | 8 | 8 | 7 | 7 | 7 | 7 | 6 | 6 | 6 | |

| 2 | Thickness, mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

| 3 | Rate deviation,% | -0.5 | |||||||||||

| 4 | Fracture strength, KN/m ≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | |

| 5 | Fracture pulling ratio ,% | 25~100 | MD/CD | ||||||||||

| 6 | CBR bursting strength, KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

| 7 | Equivalent aperture 0(0) mm | 0.07~0.2 | |||||||||||

| 8 | Infiltrate parameter vertically, cm/s | K×(10-1-10-3) | K=1.0-9.9 | ||||||||||

| 9 | Tearing strength, KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | MD/CD |

| Packaging Detail:Plastic tube+black PE membrane |

| Delivery Detail:One 40HQ within 10 days |