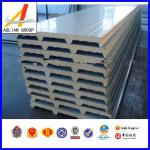

Tosolbond Fiberglass Honeycomb Panel for Wall Cladding

| Product Name | Fiberglass Honeycomb Panel |

| Material | aluminium alloy plates, roller coated with PVDF, while in the middle is the aluminium honeycomb which meets the American Military Standards |

| Techonology | Made with a special manufacturing method called cold-glue and hot-press technology. This special process ensures the product to be remarkably superior to any other products in the market. |

| Application | widely used for architectural applications like wall cladding and interior / exteriors walls’ decoration. |

| Size | Standard Size 1200 x 2400mm or 1000 x 2000mm Maximum Size 1600 x 4000mm We can cut to any size according to requirments |

| Hexagonal Side | Cell Size | Foil Thickness | Maximum Expanded Size | |

| 0.9 | 1.56 | 1/16 | 0.025 | 600 x 1850 |

| 2 | 3.46 | 1/8 | 0.04, 0.06 | 1600 x 1600 |

| 6 | 10.38 | 3/8 | 0.04, 0.06 | 1600 x 3100 |

| 7.5 | 12.98 | 1/2 | 0.04, 0.06 | 1600 x 3800 |

| 10 | 17.3 | 3/4 | 0.04, 0.06 | 1600 x 5000 |

| 15 | 25.95 | 1 | 0.04, 0.06 | 1600 x 7500 |

| 20 | 34.6 | 13.8 | 0.04, 0.06 | 1600 x 10000 |

Technical Details:

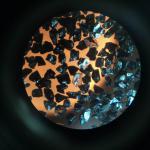

Early in the forth century, the Greek mathematician, Pepose declared that the smart shape of honeycomb is the representative of the most effective labor of the nature. At that time, he guessed "the hexagon honeycomb which mankind can see is made with the least bees' wax."

When modern engineering science looked for a material possessing highest strength to weight ratio, they couldn’t find anything other that honeycomb structures. These honeycomb structures are manufactured by using lightweight sandwich panels with other advanced materials which, when combined, can be manufactured into flat or curved panels and possess one of the highest strength to weight ratios of any structural material available on the market today.

TOSOLBOND Aluminium Honeycomb Panels are made from aluminum honeycomb core, expanded into a hexagonal structure sandwiched by the aluminum facings, which are then bonded together by a layer of adhesive. These sandwich panels utilizing aluminum honeycomb cores result in lightweight, high strength structures that are very rigid. Aluminum honeycomb panels have the best strength to weight ratio of any construction material available today.

Advantage Feature

The key is in the design. TOSOLBOND honeycomb cores are up to 95% open space, with a density of 16 to 48 kg/m3. When bonded to a facing material on both sides, the resulting I-beam-like performance carries shear, bending, and compressive loads. And like an I-beam web, the thicker the honeycomb, the greater its load carrying capacity.

TOSOLBOND Honeycomb is exceptionally versatile. Its thickness and density can be adapted to any design challenge. It can be bonded to an infinite variety of facing materials, and it can be sized, shaped, and curved for virtually any application.