Top class USA GRI-GM13 standard ASTM double side smooth HDPE geomembrane - YGGEOMEMBRANE-07

| Type: Geomembranes | Place of Origin: Hebei China (Mainland) | Brand Name: YG | Model Number: YGGEOMEMBRANE-07 |

| Material: HDPE |

Top class USA GRI-GM13 standard ASTM double side smooth HDPEgeomembrane

Product Introduction

When it comes to quality consistency, product range and best service to the customers,

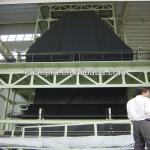

Our manufacturing facilities include German state-of-the-art technologies.

We have successfully handled various projects with hazardous chemical waste landfills,

municipal solid waste landfills, large water bodies, containment bodies and other environmental applications.

Product Application

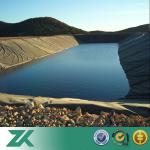

1. Environmental protection and sanitation like waste landfill, sewage treatment, industrial waste, etc.

2. Water conservancy such as anti-seepage, leakage blockage and reinforcement of river, etc.

3. Municipal projects such as underground project, subway, planting roof, etc.

4. Landscape garden such as artificial river, bottom lining, damp-proof, etc.

5. Mine industry such as bottom lining and anti-seepage

6. Traffic facilities such as road foundation and anti-seepage of subway and culvert.

7. Agriculture such as anti-seepage of ditch, channel, reservoir, pool and irrigation system.

Product Featue

- Good physical and mechanic performance

- High tearing resistance, strong deformation adaptability

- Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

- Good adaptability to high and low temperature, non-toxicity, long service life

- Good waterproof, drainage, anti-seepage and damp proof effects

- Complete width and thickness specifications, low cost and easy installation.

Product Standard

No. | Item | Test Value | ||||||

| 0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

| 1 | Minimum Density(g/cm³) | 0.939 | ||||||

2 | Tensile Property | |||||||

| Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

| Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

| Elongation at yield,% | 12 | |||||||

| Elongation at break,% | 700 | |||||||

| 3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

| 4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

| 5 | Stress Crack Resistance, hrs | 300 | ||||||

6 | Carbon Black Content, % | 2.0-3.0 | ||||||

| Carbon Black Dispersion | 1 or 2 | |||||||

7 | Standard OTI Min | 100 | ||||||

| High Pressure OTI Min | 400 | |||||||

| 8 | Impact Cold Crack at -70°C | Pass | ||||||

| 9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-16 | ||||||

| 10 | Dimensional Stability (%) | ±2 | ||||||

| Packaging Detail:with woden fabric or as per request |

| Delivery Detail:within 10-15 days once we receive the deposit |