Thermal insulated aluminium profile to windows and doors

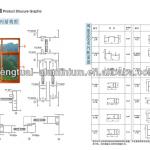

| Place of Origin: Shandong China (Mainland) | Brand Name: Xindadi | Frame Material: Aluminum Alloy | Open Style: Swing |

| Type: Casement Windows | Opening Pattern: Horizontal | Thickness wall: ≥ 1.2 mm | Surface treatment: wood grain and electrophoresis |

| Certificate: ISO 9001 | Pattern: heat insulated | Payment terms: T/T, L/C | Lead time: 20 days |

|

Surface treatment: mill finish, anodized oxidation, electrophoresis, powdercoating, wood grain series

Temper: T5/T6

National standard: GB 5237 (referenced with EN 12020)

Chemical composition: GB/T 3190(EN 573-3)

Tolerance on dimensions and form: YS/T 436 (EN 12020-2)

Mechanical properties:GB/T 228-2002(EN 755-2)

Tensile test: EN 10-002-1

Surface finish: EN 12020-1 2001

Hardness testing: EN ISO 6506-1

AA 6063 is an aluminium alloy, with magnesium and silicon as the alloying elements. The standard controlling its composition is maintained by The Aluminum Association. It has generally good mechanical properties and is heat treatable and weldable. It is similar to the British aluminium alloy HE9.

6063 is mostly used in extruded shapes for architecture, particularly window frames, door frames, roofs, and sign frames. It is typically produced with very smooth surfaces fit for anodizing.

Chemical composition[

The alloy composition of 6063 is:[1]

- Silicon minimum 0.2%, maximum 0.6% by weight

- Iron no minimum, maximum 0.35%

- Copper no minimum, maximum 0.10%

- Manganese no minimum, maximum 0.10%

- Magnesium minimum 0.45%, maximum 0.9%

- Chromium no minimum, maximum 0.10%

- Zinc no minimum, maximum 0.10%

- Titanium no minimum, maximum 0.10%

- Other elements no more than 0.05% each, 0.15% total

- Remainder Aluminium

Mechanical properties

The mechanical properties of 6063 depend greatly on the temper, or heat treatment, of the material

6063-T5

T5 temper 6063 has an ultimate tensile strength of at least 22,000 psi (152 MPa) in thicknesses up to 0.5-inch (13 mm), and 21,000 psi (145 MPa) from 0.5 to 1.0-inch (25 mm) thick, and yield strength of at least 16,000 psi (110 MPa) up to 0.5-inch (13 mm) and 15,000 psi (103 MPa) (from 0.5 to 1.0-inch (25 mm). It has elongation of 8%.

6063-T6

| Packaging Detail:protective plastic film + kraft. |

| Delivery Detail:20 days |