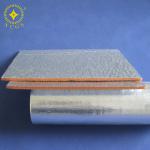

T&G Edge XPS foam boad, Styrofoam, Extruded polystyrene foam,Insulation materials

T&G Edge XPS foam boad, 1. T&G edge, 2. Low thermal conductive, 3. Energy Saving - details see: https://www.buildingsupplieshub.com/t-g-edge-xps-foam-boad-styrofoam-extruded-polystyrene-foam-insulation-materials-10075954

| Type: Other Heat Insulation Materials | Place of Origin: Jiangsu China (Mainland) | Brand Name: Feininger | Raw Material: polystyrene |

| Fire rate: B1/B2 | Color: Blue/yellow/red/green(Or any) | Length: 1200-2400mm | Width: 600-1200mm |

| Egde shape: T&G |

Feininger XPS Foam Board:

T&G Edge XPS foam boad, Styrofoam, Extruded polystyrene foam,Insulation materials

- Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

- Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

- Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

- Lightweight: volume optimization and easy to handle

- Resistance to deformation

- Resistance to impact

- Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendly - Recyclable: Polyfoam can be 100% recyclied

T&G XPS foam board :

Technical Data Sheet:

Item | Unit | Property Index | |||||||||||

With Skins | |||||||||||||

| X150 | X200 | X250 | X300 | X350 | X400 | X450 | X500 | ||||||

Compressive Strength | KPA | ≥150 | ≥200 | ≥250 | ≥300 | ≥350 | ≥400 | ≥450 | ≥500 | ||||

Water Absorption, | %(by volume) | ≤1.5 | ≤1.0 | ||||||||||

dipped in water for 96h | |||||||||||||

Moisture Permeability, 23°C±1°C,RH 50%±5% | Ng/(m.s.Pa) | ≤3.5 | ≤3.0 | ≤2.0 | |||||||||

Heat Insulation | Heat Resistance Thickness25mm 10°C 25°C | (m2·K)/W | ≥0.89 ≥0.83 | ≥0.93 ≥0.86 | |||||||||

| Heat Conductivity Average Temp. 10°C 25°C | W/(m·K) | ≤0.028 ≤0.030 | ≤0.027 ≤0.029 | ||||||||||

DimensionalStability 70°C±2°C, 48h | % | ≤2.0 | ≤1.5 | ≤1.0 | |||||||||

4 Different Edge Shape :

4 Different Surface Type:

Package & Loading

Certificates:

| Packaging Detail:By polybag |

| Delivery Detail:5-15 working days |