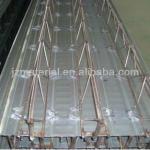

steel deck with reinforced steel truss TD-70 TD-90 TD-120 TD-150 steel truss deck /metal decking sheet - TD-70, TD-90, TD-120, TD-150, TD-200, TD-270

| Place of Origin: Zhejiang China (Mainland) | Brand Name: Jinzhan | Model Number: TD-70, TD-90, TD-120, TD-150, TD-200, TD-270 | Material: Galvanized Sheet |

| Zinc coating: Z80g/m2-275g/m2 | steel sheet material: Q235,Q345 | Width: 576mm/600mm | Steel sheet thickness: 0.50/0.60mm |

| Length: 1m-12m | Height:: 70mm-270mm | Top and bottom bar diameter:: 6-12mm | Distributing bar diameter: 4-10mm |

| steel bar material: CBR550 or HPB235 | Standard: AISI, ASTM, BS, DIN, GB, JIS |

Steel bar truss decking sheet

Instead of normal concrete formwork and composite steel decking. our product have advantage as follows:

1)saving labor,time,cost. (easy assemble,reinforced bar be prefabricated )

2)better mechanical structure model.

3)no fire resistant and corruption maintain demand.(compare with steel deck)

widely applied in steel structure floor,roof,steel-concrete composite slab

| composite Steel decking | steel bar truss decking | |

| Final concrete slab | Thick | SHALLOWER, saving space,saving concrete cost |

| installation | easy | easy |

| reinforcement | Welding steel mesh | Steel bar. Saving cost |

| Plate(steel sheet) | AS SHEAR BONE,Bearing the loading after concreting | Just as PERMANENT formwork. .useless after concreting |

| Plate Fire protection | demand | No need |

| Plate corrosion protection | Maintenance demand.* specially around stud place where sheet harmed after welding | No need Perfect performance in marine environment |

| across direction layout | Difficult to design&settle | Easy to settle |

| Mechanical property | good | better |

| Seismic performance | bad | good |

| Integrate cost | high | low |

| Comfort due to slab autooscillation | bad | good |

At present, multistory and tall building usually take profiled steel sheet with some ribs -concrete composite floor,which has the disadvantages of high thickness, reducing inner height of building, unflattering of under floor, lots of reinforcement binding, hard control of distances between ribs and thickness of concrete.

To solve these problems, we research and develop the Third Generation profiled steel products-Steel Truss Deck.

Specifications:

1. Top bar diameter : from 5-12mm

2. bottom bar diameter :from 5-12mm

3. Distributing bar diameter: from 4-10mm

4. bar length:from 3-12m

5. girder width:100-150mm

6. girder height: from 100-150mm

Applications:

1 Applied to precast slabs, pre-high-speed railway sleeper.

2 Used in many high-rise, ultra- high-rise steel buildings

3 Used for steel building, mezzanine floor of “LOFT”

4 The force applied to the complex, special-shaped structure, building

5 Used in-situ concrete structure(RC) buildings

6 Used in the construction of slope roof structure

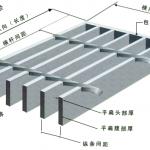

Product shape

Truss deck system structure include TDA and TDB Truss deck structure

TDA Truss deck system (576mm)

TDB Truss deck system(600mm)

Process flow

Drawing up operation plan →Truss deck in site→ handing& temporary setting→

Truss deck installation→ side formwork setting → Male pin welding→

Line pipe set→ additional steel bar →clearance& inspection → concrete placing

| Width | 576mm/600mm |

| Maximum length | 1m-12m |

| Height | 70-270mm |

| Top and bottom bar diameter | 6-12mm |

| Brace bar diameter | 4-10mm |

| Decking thickness | Galvanized steel sheet 0.5mm/0.6mm/0.70mm |

Common specifications:

| No. | Item | Description |

| 1 | Top Steel Bar Size | φ 8mm, φ10mm, φ12mm, etc. |

| 2 | Bottom Steel Bar Size | φ 8mm, φ10mm, φ12mm, etc. |

| 3 | Cross Steel Bar Size | φ 4.5mm, φ5mm, φ5.5mm, φ 6mm, φ7mm, φ8mm, etc. |

| 4 | Base Plate Size | Width: 576mm or 600mm, Thickness: 0.5/0.6mm, Galvanized Surface |

| 5 | Truss Height | 70mm, 80mm, 90mm, 100mm, 110mm, 120mm, ..................270mm |

| 6 | Surface Treatment | Black, self colour |

| 7 | Standard | China: JG/T 368-2012 |

Steel Bar Truss Decking Size:

TD1-70,TD1-80,TD1-90,TD1-100,TD1-110,TD1-120,TD2-70,TD2-80,TD2-90,TD2-100,TD2-110,TD2-120,TD2-130,TD2-140,TD2-150,TD2-160,TD2-170,TD3-70,TD3-80,TD3-90,TD3-100,TD3-110,TD3-120,TD3-130,TD3-140,TD3-150,TD3-160,TD3-170,TD4-70,TD4-80,TD4-90,TD4-100,TD4-110,TD4-120,TD4-130,TD4-140,TD4-150,TD4-160,TD4-170,TD4-180,TD4-190,TD4-200,TD4-210,TD4-220,TD4-230,TD4-240,TD4-250,TD4-260,TD4-270,TD5-70,TD5-80,TD5-90,TD5-100,TD5-110,TD5-120,TD5-130,TD5-140,TD5-150,TD5-160,TD5-170,TD6-70,TD6-80,TD6-90,TD6-100,TD6-110,TD6-120,TD6-130,TD6-140,TD6-150,TD6-160,TD6-170,TD6-180,TD6-190,TD6-200,TD6-210,TD6-220,TD6-230,TD6-240,TD6-250,TD6-260,TD6-270,TD7-70,TD7-80,TD7-90,TD7-100,TD7-110,TD7-120,TD7-130,TD7-140,TD7-150,TD7-160,TD7-170,TD7-180,TD7-190,TD7-200,TD7-210,TD7-220,TD7-230,TD7-240,TD7-250,TD7-260,TD7-270

Installation:

Service & Technical Support

v Service

1. Various samples and combinations of samples

2. Recommendation to cost effective raw material(quality and price)

3. Accepting alteration before production

4. Financial credit support to special project

5. Sufficient storage and quick delivery, meeting different requirements

6. Three different criterions of packing

7. Service of transportation consignation

8. Concurrent manufacturing to the project of jobsite

v Technical Support

1. System solution consultant

2. Customised solution design

3. Initial system solution design

4. Load calculations

5. Confirmation of solution and design

6. Drawing of purlins and sheetings

7. Detail design (including trims, grade, sky light, ventilator, etc)

8. Installation instruction and fieldwork Regular PDCA quality inspect

| Packaging Detail:standard export packing |

| Delivery Detail:15days |