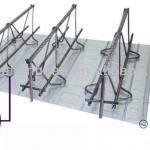

Steel bar Truss Girder Slab for construction

| Place of Origin: Shandong China (Mainland) | Brand Name: LianHuan | Material: Steel | galvanized bottom plate: steel bar |

Specification:

upper stem (mm) | Φ6-Φ12 | Φ6-Φ12 |

lower stem (mm) | Φ6-Φ12 | Φ6-Φ12 |

diagonal(mm) | Φ4-Φ7 | Φ4-Φ6 |

pitch distance (mm) | 190-210(as required ) | 190-210( as required) |

height(mm) | 100-300 (as required ) | 70-300 (as required ) |

width(mm) | 25-125 (as required ) | 75 (as required ) |

length (mm) | 200~12000 | 200~12000 |

The truss girder slab ensure the stiffness of floorslab in the construction stage, to replace the load-bearing.

Steel bar in the service stage of floorslab.

Both the diameter of steel bar and height of truss girder are adjustable.

Scientific stress design, economical material, a geniuine advantage on integrated cost.

Bidirectional floor decking is optional.

The height of truss girder rebar diameter can be ajusted to fit for large span floorslab.

Steel bar consumption is 3-5kg/m2. By reducing about 60%~70% working volume of steel bar tying, construction time could be reduced furtherly.

The truss girder slab has a good crack resistence, mechanical property of which is basically same as cast-in-place floor. Fire resistence of truss girder slab can match cast-in-place floor and is superior to profiled steel sheeting.

Rebar is arranged evenly. Distance between upper bar and lower bar, thickness of rebar protective layer is well fixed.

| Packaging Detail:GP40 container |

| Delivery Detail:20 Days |