skylight polycarbonate panels for rofing cover - ADS-PCH

| Type: Sun Sheets & PC Embossed Sheets | Place of Origin: Guangdong China (Mainland) | Brand Name: andesi | Model Number: ADS-PCH |

| thickness: 4mm-18mm | max width: 2.1m | length: not limited | standard color: clear, opal, green, blue, brown |

| guarantee: 10 years | fire retardant: B1 | uv protection: 50 micron |

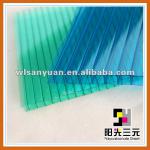

hollow skylight polycarbonate panels for rofing cover

Our mission: Use the most honest attitude to give the best service to our customers.

Specifications of crystal polycarbonate hollow sheet

Thickness: 4mm-18mm

max width: 2.1m

Length: customized

Standard color: clear, opal, green, blue and brown (special color can be customized)

Technical data of polycarbonate hollow roofing sheet

| 1 | Impact Strength | J/m | 50 |

| 2 | Thermal Expansion | mm/m·°C | 0.065 |

| 3 | Heat Conductivity | W/ m2·°C | 0.21 |

| 4 | Service Temperature | °C | -40°C~ +120·°C |

| 5 | Tensile Strength | N/mm | ≥69.1 |

| 6 | Bending Strength | N/mm2 | 68 |

| 7 | Bending Elastic Modulus | Mpa | 2120 |

| 8 | Tensile Stress at Break | Mpa | ≥130 |

| 9 | Elongation at Break | % | 130 |

| 10 | Effect of Sound Proof | dB | 35 decibel decrease for 6mm solid sheet |

The features of polycarbonate hollow sheet for roofing

1) Good light transmission: Reaches 12%- 88% depend on color and thickness.

2) Impact resistance: 250-300 times that of ordinary glass and 20-30 times that of acrylic sheeting

3) Weather resistance: -40°C~+120 °C

4) Flame resistance: Rated class B1

5) Light weight and easy installation: 1/2 of glass of the same thickness

6) Ultraviolet resistance: With UV protective layer

7) Sound and heat proof

8) Fine plasticity, either cold bending or hot bending

Applications of polycarbonate hollow sheet

1) Unusual decorations, corridors and pavilions in gardens and recreational and rest places

2) Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings

3) The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines

4) Telephone booths, street name plates and sign boards

installation method of crystal hollow polycarboante sheet

a) The diameter of the drill hole on the pc sheet should be bigger than the diameter of the screw about 50% , in case of expanding with heat and contracting with cold.

b) The distance of the drill hole on the pc sheet should be suitable, the longer distance, the larger thermal expansion. If the space of the drill hole is too short, it will limit the moving of the pc sheet.

c) The suitable distance of the drill hole on the pc sheet is 50cm. The suitable distance between drill hole and the edge of the pc sheet is about 3-5cm.

d) The diameter of the top of rivet should be the double of the shank. Make a gasket in case the pressure damages the pc sheet.

e) The screw should not tighten in case of breaking the pc sheet.

f) Should not use pvc gasket or pitch adhesive tape, because the chemical additive will be corrosive the pc sheet

g) The bending part should not use screw to fix the sheet when the sheet makes cold bend process. All the holes should use neutral silicone structural sealant to full in case the detergent permeate the edge of the sheet.

Production line & raw material:

Certificate

| Packaging Detail:PE protective film for both sides |

| Delivery Detail:7-10 days for a container |