SF4601-FG China Rose aluminum composite panel - SF4601-FG

| Place of Origin: Guangdong China (Mainland) | Brand Name: Auland | Model Number: SF4601-FG | Usage: Indoor |

| Function: Fireproof | Surface Treatment: Film Lamilated | Color and pattern: Blue Brick alike | Panel thickness: typically 1mm, 2mm, 3mm; other thicknesses available on request |

| Plastic core material: re-cycled or natural polyethylene resin, fire retardant material | Aluminum thickness: 0.1mm to 0.5mm | Panel sizes: typically 1220x2440mm, other lengths available on request | Other designs options: Botticino, Fragment-stone, Verde Alpi, Emperor Red etc |

| Applications: interior wall, partition board, decorative backdrop, cabinet cover | Technical Compliances: ASTM standards, national standard GB/T 17748 | Quality Control and Warranty: 5 years, ISO 14001, ISO 9001 certified | OEM arrangement: customer branding or private labeling is acceptable |

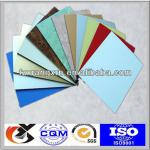

Marble alike film laminated aluminimum composite panelsare designed to provide strikingly marble alike patterns to interior designers who decide to deploy the environmentally friendly composite panels to replace marble in their interior decoration works. There are versatile choices of different designs available for selections, including Multi-Red, Camelia white, Giallo California, Imperial Red, Colophony, Tan Brown, Botticino, Arabescato, Blank Marquina, Royal Botticino, Rosa Norvegia, Emperor Red, Verdi Alpi, Portoro, Honey Beige, Emperador, Rosa Coral, Carmen Red, Gren Fragment Stone, Green Jadestone, Yellow Jadestone, White golden flower, Yellow golden flower etc.

Wide Applications

Aulanddecorative panels has been designed to fulfill the robust structural requirement as well as providing alternatives to interior designers for creating their masterpiece. They are widely used in various applications, such as cladding, partitioning board, indoor decorative wall, cabinet cover, signage board, exterior wall, ceilings, decorative door etc.

Various Patterns

Apart from marble alike film laminated series, there are other product series available from us, including PVDF series for outdoor decoration, Polyester painted series for colorful indoor decoration, Wood alike film laminated series, Crown series for high tech and glamorous decoration, High gloss pearly bright colorful film laminated series for indoor decoration, pre-anodized series for high reflection decorative requirement, marble/wood alike PVDF coated series for outdoor patterned decoration etc.

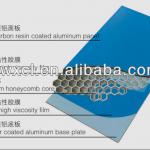

Specification and Technical Details

Our product are designed and manufactured to meet the international standards. Some technical details are highlighted as shown below.

General Specifications

Dimensions

Thickness 3mm,4mm,5mm,6mm (+/- 0.2mm)

Width 1220mm,1250mm,1500mm (+/- 2mm)

Length Less than 6000mm (+/- 4mm)

Bow Max 0.5% of any dimensions

Diagonal Lines difference Max 5mm

Physical properties Standard Measurement

Panel wight ASTM D-792 T3mm=4.6kg/m² t4mm=5.5kg/m²

Thermal expansion ASTM D-696 3X 10¯5/°c

Thermal conductivity ASTM C-519 0.39 kcal/m.hr°c (4mm)

Deformation temperature ASTM D-648 115°c

Mechanical roperties Standard Measurement

Tensile Strength ASTM D-638 49Mpa

Yield Strength ASTM D-638 44Mpa

Bending Strength ASTM D-790 120Mpa(4mm)

Flexural Elasticity ASTM D-790 2.6X10000Mpa(4mm)

Shearing Strength ASTM D-732 33 Mpa

Penetrating Resistance ASTM D-732 11 KN

Adhesive Peel Off Strength ASTM D-903 10N/mm

Wind Pressure resistance ASTM D-330 Passed

Resistance against water ASTM D-331 Passed

Resistance against air ASTM D-283 Passed

Processing Method

Aulandaluminimum composite panels are easy to use. During installation, saw cutting, shear cutting, grooving, punching, perforating, drilling are possible by deploying common metalwork and woodwork machines. Bending and folding are done by grooving the back skin using router or trimmer.

Packing

There are two typical packing method for container loading:

a. The panels can be loaded and stacked firmly together inside the containers with overall wooden and metal frame support to ensure no movement within the container during sea transportation. Re-enforced iron tapes are used to hold the stacked panels together.

b. Another option is to pack 100-300 panels into pallets, firmly hold them together using re-enforced iron tape and then stored the pallet into wooden box before loading into the containers. Additional enforcement structure will be added inside the container to avoid movement of boxes during transportation when required.

| Packaging Detail:There are two typical packing method for container loading: a. The panels can be loaded and stacked firmly together inside the containers with overall wooden and metal frame support to ensure no movement within the container during sea transportation. Re-enforced iron tapes are used to hold the stacked panels together. b.Another option is to pack 100-300 panels into pallets, firmly hold them together using re-enforced iron tape and then stored the pallet into wooden box before loading into the containers. |

| Delivery Detail:25 days |