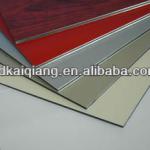

PVDF aluminum composite panel - YC214

| Place of Origin: Zhejiang China (Mainland) | Brand Name: Alucobond | Model Number: YC214 | Usage: Outdoor |

| Function: Anti-Static,Antibacterial,Mould-Proof | Surface Treatment: PVDF Coated |

Fluorocarbon Aluminum composite panel is made of a mixture of fluorocarbon resin with fluorine enyne as the basic monomer, paint, alcohol ester solvent and accessory ingredients. The molecular structure in the coating is compact after being high bakeed into film formation, which has extra-strong weather resistance. The fluorocarbon coating falls into conventional fluorocarbon coating and nano fluorocarbon coating according to the structure of film formation on the surface.

A.Conventional fluorocarbon is made of KYNAR500 fluorocarbon and is solidified into film formation on the surface after three coat and three bake. It is acid & alkali resistant standing the test of severe environment, and has no abnormal depigment for 15 to 20 years, which is more applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

B.nano fluorocarbon is made of matured fluorocarbon surface processed with an additional coating of stain resistant layer added with nano materials. The coating after film formation has an extra low surface tension, which is stain resistant and can achieve the cleaning of surface coating simply by natural rain washing.

Our company is specialized in producing aluminum composite panel(ACP),aluminum coil and ACP production line machines.

Decorative materials

1) Standard dimensions (width x length x thickness):

a) 1,220 x 2,440 x 3mm

b) 1,220 x 2,440 x 4mm

2) Specifications

Thickness:1mm,2mm,3mm,4mm,5mm,6mm,etc.

Width:1,000mm, 1,220mm, 1,250mm, 1,550mm, etc.

Length:2440mm--6000mm ,upon customers' requests

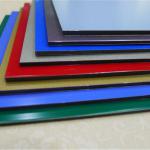

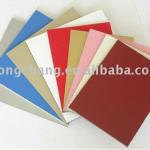

3) Normal color:

38 kinds for normal aluminum composite panel

4)Material:

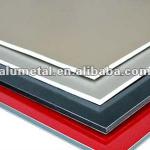

a) Front: aluminum alloy sheet coated with Polyvinylidene Fluoride(PVDF)

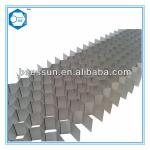

b) Core: nontoxic polyethylene(LDPE)

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF resin rolling roasting coating

5)Characteristics:

a) Super peeling strength

b) Excellent surface flatness and smoothness

c) Superior weather, corrosion, pollutant resistance

d) Even coating, various colors

e) Fireproof, excellent heat and sound insulation

f) Superior impact resistance

g) Lightweight and easy to process

h) Easy to maintain

6)Application scope:

a) Building exterior curtain walls

b) Decoration and renovation additions for old buildings

c) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

d) Shop door decorations

e) Advertisement board display platforms and signboards

f) Wallboards and ceilings for tunnels

g) Industrial materials, materials for vehicles and boats

| Packaging Detail:wooden pallet or in bulk |

| Delivery Detail:7-14days |