PU sandwich panels

| Place of Origin: Shandong China (Mainland) | Brand Name: BAIKAL | Panel Material: Metal | Type: Polyurethane Sandwich Panels |

| weight: 3.6kg/piece | area: 1.444sqm/piece | size: 3800*380*16mm | package size: 3800*415*135mm |

| package quantity: 8pieces/carton | thermal conductivity: 0.024w(m*k | water absorption: 415% |

| Testing report of Physical performance | |||||||

| testing item | technical requirement | testing result | testing method | ||||

| thermal conductivity (core material/W(m*k) | ≤0.040W(m*k) | 0.024 | GB/T 10297-1998 | ||||

| compressive strength,kpa | ≥30kpa | 52.7 | JG149-2003 | ||||

| water absorption,% | ≤424% | 415% | JG149-2003 | ||||

| density of the panel (three layers),kg/sqm | ≥1.7*100 | 1.821*100 | GB/T 6343-1995 | ||||

| bending resistance under 0.5KN,mm | ≤18.3 | 13.3 | GB/T 9341-2000 | ||||

| cementation strength,Mpa | >0.1 | 0.18 | JG149-2003 | ||||

| smog resistance(h) | / | no spot of erosion, no color change | GB 5938-1986 | ||||

| weather resistance(h) | / | no damage on surface,color changes on level 4-5 | GB/T 17657-1999 | ||||

| oxygen index, % | >26 | 26.1 | GB/T 2046-1993 | ||||

| horizontal burning of PU | everage burning time ≤90s | 77 | GB/T 8332-1987 | ||||

| everage burning area ≤50mm | 37 | GB/T 8332-1987 | |||||

| wind resistance data,Kpa | / | 8 | JG149-2003 | ||||

| Insulation performance comparison | |||||||

| testing items | gypsum board | common outer wall | sandwich panel | ||||

| thermal conductivity | 0.5 | 0.15 | 0.018 | ||||

| the comparison of thickness | 27.8cm | 8.34cm | 1.0cm | ||||

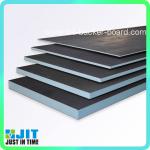

structure of the steel board:

section close-up :

1.easy construction

Construction is convenient, quick, labor saving, not only reduces the workers’ on site operation procedure and time but also reduces the comprehensive cost.For exterior wall renovation, treatment of base is no longer needed,it can be directly fixed on the original wall. Its cost is less than any product of the same kind in current building material market.

2.Significant energy saving effect

"Baikal" sandwich panel integration system is mainly the following four key energy saving technology: a special aluminum zinc plate, rigid polyurethane foam, reflective film, air layer.The “Baikal sandwich panel” substrate using aluminum zinc plate thickness 0.27to0.30mm, surface by pressure balance principle of the enhancement layer strength greatly, but also improves the decorative effect, finishes can be pressed into a variety of different styles of texture, can satisfy the different grades of decorative needs, enhance the building facade image, to inject a new vitality the appearance of the building. More effectively save the energy reuse. (aluminum zinc plate theory of life for more than 45 years, and the recovery rate was 99.9%.).

3. Stronger decorative effect and more options:

In order to provide customers with more choices and to give more space for architectural design,the company introduced over a hundred kinds of relief patterns matching with different colors.Luxurious and beautiful decorative effect highlights the class and grade of the construction. Dismounting method is simple and flexible,making the replacement of the metope easy. we can also make certain color as customers required. Combination of different patterns and colors forms the inventive and changeful construction style.

4. Be widely used:

Application of metal exterior wall panels can be widely used in municipal construction,residential apartments, villas, gardens, the transformation of old buildings, the guard post and many other engineering fields. The material is suitable for the new masonry structure, frame structure, steel structure, light body housing and other types of buildings;It's also suitable for old houses' reconstruction of decoration and energy saving,and decoration of indoor and outdoor. Metal exterior wall panel is going to be the first choice in the wall building materials market.

Factory Show:

| Packaging Detail:package size:3800*415*135mm ; package quantity: 8 piece/carton |

| Delivery Detail:3-7days |