Professional Manufacturer Wide Span Light Steel Structure Building House - HGSS-001

| Place of Origin: Zhejiang China (Mainland) | Brand Name: Handgen | Model Number: HGSS-001 | Main structure: H type column,Z/C type purlin |

| Wall system: Colored steel sheet or PU / EPS sandwich board | Roof system: Colored steel sheet or PU / EPS sandwich board | Floor/foundation: Concrete | Complement: Skylight and ventilator |

| Insulation: Glass wool | Window: Aluminum alloy or plastic steel | Door: Steel door or sandwich panel door | Color: White,blue,gray,red,camouflage ect. |

| Service life: 30 years |

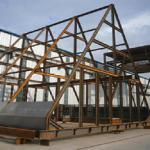

Steel structure project is third generation construction, it adopts H type steel, C type steel and Z type steel to combine or build framework, roof and wall are color steel compressing corrugated steel or color steel sandwich panel, steel structure building has basically substituted traditional reinforced concrete in developed country.

- 1) It has many excellent characteristics like light weight,large span,and structural stability.

- 2) Also use few materials,and can be used several times that is can be recycling,so it's low cost and economy.

- 3) Besides,it has a long life-span up to 50years for use.At the same time,due to the materials it uses,the wall and roof structures take full account of the heat insulation, moisture-proof effect, which saving a lot of energies.

- 4) What's more,it used widely,such as monolayer workshop, storage, business architecture, office block, several park and family house etc.

- 5) One point more worth noting is that all of the steel frame components may be galvanized to address customers' demands; roof and wall finished can be more a variety of colors, shapes, and other options, and thus greatly improve the aesthetic appearance of the design, sufficient to meet the customers' requests.

The detailed structure of Steel Structure Building:

Steel Metal Building Frame Types:

Steel Structure Building Wall & Roof Panel Types:

Packaging Detail: Flat packing, main structure packed in an integrated rack made by H beams, other parts packed in cartons or crates, all loaded into 40FT HQ. Safe and easy handling.

Delivery Detail: Depends on the building area

HANDGEN CORP. is committed to high-rise steel structure building field and has expanded building functional applications. It includes hotels, guest houses, offices, banks, office buildings, supermarkets, shopping malls, the Conventions and Exhibitions, hospitals and radio and television towers.

The type of building structure involves:

1. All-steel structure

2. Steel - concrete composite structure

3. The structure of the portfolio, and so on.

The system of building structure involves:

1. Steel frame structure

2. Steel frame – support structure

3. Steel framework – concrete shell structures

4. Steel Framework –concrete wall structure

5. Steel truss framework –support structure

6. Steel truss framework –concrete structure of the cylinder

7. Tube-in-tube structure

8. The support structure of giant framework.

STEEL STRUCTURE MEMBERS PRODUCTION (Fabrication) PROCESS

1. Prepair raw materials : cut steel plate or use internation size H section steel and angle steel,round tube,round steel,square tube etc.;

2. Assembly and welding: our welders will follow the drawings to assembe the steel members and weld them together as a entire beam/column/brace and so on; (Our quality inspector will check the steel pieces after finish welding,this is the first quality check)

3. Sand blast : After finish welding and polishiing,our sand blast effect can reach internation 2.5 high grade,very good for resist rust; (Secondary quality check)

4 .Paint : Within 2 hours after sand blast,all the steel members should be paint. Client can choose any color and any brand of paint. (The third quality check)

5. Inspect the goods by client : After we finish a part of fabrication work,we will invite clients to check the goods before we pack the steel frame.

6.Packing and loading : If clients require us to load the goods by close containers,we will pack the steel structure members one by one on the steel skid and tie the whole steel package well. (The fourth quality check )

If you really interested in Prefabricated Steel Structure building, and would like we do the design for you, please give me the following information:

All the frame is steel structure, wall and roof is color steel corrugated sheet, sandwich panel or other plate, and we can customized under your requirement. But we need some info of steel structure project. Our products are all customized. May i know more about your requirements(such as size, wall and roof use what materials, bick wall height, crane capacity,etc).

1. Dimension: Length, width, height, eave height, roof pitch, etc.

2. Doors and windows: Dimension, quantity, position to put them.

3. Local climate: Wind speed, snow load, etc.

4. Insulation material: Sandwich panel or steel sheet.

5. Crane beam: Do you need crane beam inside the steel structure? And its capacity.

6. Is there any materials that are not allowed to import into the country where the structure is planning to use?

7. If you have other requirements, such as fire proofing, isolated roof, etc, please also inform us.

8. It's better if you have your own drawings or pictures. Please send them to us.

Our strong points(advantages) :

1. Sand blast: The sand blast effect reach 2.5 high grade,many countries with high standard requirements accept 2.5 grade.

2. Welding: Our welders are full of experiences,professional in butt weld,fillet weld,intermittent welding etc.The welding lines are straight,orderly and nice.

3. Painting: We use hight pressure airless spraying machine for painting,both the color and the thickness of paint are well-proportioned.

4. Packing: (1) Open top container(advantage:easy to load the steel;disadvantage:high shipping cost,aleak and few quantity);

(2) Closed container with steel skid (advantage:save shipping cost,all members be packed together and reduce friction,the surface of steel members will be much better;save labor cost to unload the steel members).

Oversea Sample Projects

If this is intrested you ,pls contact me to know more.

| Packaging Detail:(1) packing the pipes into the bundles by the steel strip (2) packing the welded steel structure parts by some fabric (3) packing the small parts by bags and EPS foam (4) packing sets parts by some box. |

| Delivery Detail:20 days to 25 days after receiving 30% deposit in advance. |