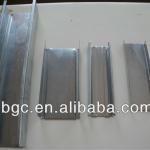

professional aluminum profile for interior door

1.professional aluminum profile for interior door, 2.Finish: Anodizing, powder coating,wood colour, polishin - details see: https://www.buildingsupplieshub.com/professional-aluminum-profile-for-interior-door-10077878

| Place of Origin: China (Mainland) | Brand Name: Brilliance Alu | Open Style: Automatic | Surface Finishing: Finished |

| Type: Cabinet Doors | Door Material: Aluminum Alloy | Certification: ISO9001 | standard: DIN AMA |

| Alloy: 6063/6061/6005/6060 T5/T6 | Finish: Anodizing, powder coating, wood clour, polishing, brushed | Procedure: Preciously Cutting, milling, drilling, punching, CNC machining | Focus On: Architecture,Industry,Home Appliance |

professional aluminum profile for interior door

TABLE OF CHEMICAL COMPOSITION OF ALUMINUM ALLOY | |||||||||||

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | 0.45-0.9 | <0.35 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.8-1.2 | <0.7 | 0.15-0.4 | <0.15 | <0.25 | 0.04-0.35 | <0.15 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.05 | <0.1 | <0.05 | <0.15 | Surplus |

TABLE OF CHEMICAL COMPOSITION OF ALUMINUM ALLOY | |||||||||||

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | 0.45-0.9 | <0.35 | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.8-1.2 | <0.7 | 0.15-0.4 | <0.15 | <0.25 | 0.04-0.35 | <0.15 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | ≤0.1 | ≤0.1 | ≤0.15 | ≤0.05 | <0.1 | <0.05 | <0.15 | Surplus |

ADODIZINMG QUALITY | ||||

Grade | corrosion resistance | abrasive resistance | ||

CASS test | alkaline dropping test | sandtrial | ||

| hours | grade | |||

| AA10 | 16 | ≥9 | ≥50 | ≥300 |

| AA15 | 32 | ≥9 | ≥75 | ≥300 |

| AA20 | 56 | ≥9 | ≥100 | ≥300 |

| AA25 | 72 | ≥9 | ≥125 | ≥300 |

| POWDER COATING QUALITY | ||||||||

| Gloss values | Thickness(um) | color variation | indentation resistance | adhesion | impact resistance | cupping test | presentation quality | |

| Max Thickness | Min Thickness | |||||||

| 60 | ≤120 | ≥40 | Color should be consistent with the sample color | ≥80 | 0 | No cracking and shedding phenomenon after the front impact test,small fine lines around the concave is allowed | No cracking and shedding phenomenon after the cupping test(6mm indentation depth ) | The surface of the decorative profiles should be smooth and uniform. wrinkle,clamminess is not allowed. |

| APPLICATION | |||||||||

| Architecture | Door and window | Curtain wall | Louver | Handrail | Barrier | Gutter detritus | Shower enclosure | Solar panel | fence |

| Industry | Assemble lines | Heat sink | Ventilation | Transportation | |||||

| Home appliance | Furniture parts | Chair | Table | White board | Ladder | Pet crate | Curling irons | ||

| Packaging Detail:plastic and kraft paper |

| Delivery Detail:2weeks |