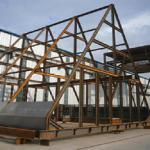

pre engineered metal frame steel structure prefabricated workshop - as per request

| Place of Origin: Tianjin China (Mainland) | Brand Name: zhongjie | Model Number: as per request | Type:: Light |

| Application:: Steel Workshop | surface:: anti-rust painting, hot galvanized | steel frame:: truss | roof/wall cladding:: sandwich panel and single corrugated sheet |

| Lifetime:: 50 years |

pre engineered metal frame steel structure prefabricated workshop

Steel prefabrication plant description:

Certificate:ISO9001:2000

Oversea markets&domestic market

Steel grade: Q235/Q345

Easy to install,fire proof,good insulation

Materials: Q235B or Q345B steel;

Coating: Epoxy zinc-rich anti-rust paints;

Applications: workshop/warehouse/machine shop

Widely applicable in kinds of industrial plants, shopping malls, exhibition halls, leisure buildings, warehouses, steel storages, sports venues, workshops, railway stations, extension projects, and roof constructions, etc. Needing more steel structure products, pls contact us at your convenience.

1> . The main structure( welding H section steel)

Steel material: Q345, Q235.

Preservative treatment: two layer primer and two layer

paint light gray (total thickness: 100-120um).

2> . The secondary structure( C purlin, steel bracing, tie- bar, knee- brace, support for steel beam and column, etc)

Steel material: Q235

Preservative treatment: two layer primer and two layer epoxy paint light gray .

3> . Corrugated steel sheet or Sandwich panel for Wall and roof panels.

1. Panel type: 1150 ,960, 950

2. Galvanized steel sheet: 60-70g/m2

3. Corrugated steel sheet(Inner and outside): 0.3, 0.4, 0.5,0.6,0.7,0.8mm

4. Sandwich panels: EPS, Rock wool, fiberglass, PU.

EPS Foam Density of EPS: 8kg-18kg/m2, Rock wool density: 80kg/m³-160kg/m³.

5. Roof and wall panel thickness: 50mm-150mm

6. Color of steel sheet: sea blue, white grey and bright red.

steel structure suitable Style:

large-scale manufacturing factory, logistics, warehousing, supermarkets, entertainment centers and other large-scale construction

steel structure Characteristics:

Fast construction, easy installation, stable structure, earthquake proofing, water proofing, energy conserving and environmental protection, etc.

steel structure Packing and Delivery:

Depends on detail structure, normally for the aim to protect steel structure components in the delivery, we suggest to use OPEN TOP containers. GP container is acceptable too.

If you really interested in our steel structure, and would like we do the design for you, please give me the following information:

1. Dimension: Length, width, height, eave height, roof pitch, etc.

2. Doors and windows: Dimension, quantity, position to put them.

3. Local climate: Wind speed, snow load, etc.

4. Insulation material: Sandwich panel or steel sheet.

5. Crane beam: Do you need crane beam inside the steel structure? And its capacity.

6. Is there any materials that are not allowed to import into the country where the structure is planning to use?

7 .Any requirements let me know we will do the best.Certainly if you can provide us the drawing which you are need is the best.

ISO9001:2000

| Packaging Detail:Normal packing or As per customer's detail requirement |

| Delivery Detail:20~30 days after the deposit received |