PP geocell/pe geocell/hdpe geocell for retaining wall with ASTM standard - DTGS

for stabilizing highway bed, bearing dike and retainung wall, supporting pipeline and sewer, flood prevention - details see: https://www.buildingsupplieshub.com/pp-geocell-pe-geocell-hdpe-geocell-for-retaining-wall-with-astm-standard-10058262

| Type: Geocells,with holes or not,Other Waterproofing Materials | Place of Origin: Shandong China (Mainland) | Brand Name: EASTAR | Model Number: DTGS |

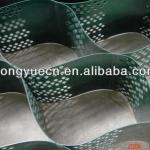

| material: HDPE | color: black, yellow, dark green | height: 5mm-40mm | welding distance: 300mm-1000mm |

| expanding size: 4.5x5m2, 6.5x4.5m2, 13.2x4.5m2 | hole diameter: usually 10mm | weld tensile strength: >=1000N/10cm | low embrittlement temperature: <=-23℃ |

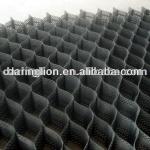

High quality HDPE geocell for retaining wallis made of welding high tensile HDPE broad bands. It has many cells and is very flexible.

It can be divided into four types

1. smooth surface without hole

2. smooth surface with hole

3. textured surface with hole

4. textured surface without hole

It can be replicated when transported and stretched to be filled with stones and soil when used, which can be as cushion coat to reinforce the soft base , and also to protect the slope when laid in the slope surface.

Applying Area

1.Be used for firm the roadbed of railroad;

2.Be used for firm highway soft foundation handling;

3.Be used for dike and retaining wall, which can bear load force;

4.Be used to harness the shoal water runway;

5.As pipeline and the sewer's propping up structure;

6.Be used for mixed type retaining wall that prevent the slope from falling down and bear load force;

7.Be used for independent wall, dock and breakwater;

8.Be used to harness the desert, beach and riverbed ,river bank

1.Be used for firm the roadbed of railroad;

2.Be used for firm highway soft foundation handling;

3.Be used for dike and retaining wall, which can bear load force;

4.Be used to harness the shoal water runway;

5.As pipeline and the sewer's propping up structure;

6.Be used for mixed type retaining wall that prevent the slope from falling down and bear load force;

7.Be used for independent wall, dock and breakwater;

8.Be used to harness the desert, beach and riverbed ,river bank

Construction method

1.Unfolding the geogrid (Some fiber-material can be put under the geogrid according to the concrete condition,for example geotextile and felted cushion.)

2.Fixing it with nail or connecting with the frame of stretcher;

3.Used loader to fill with filler until it is full top and beyond of the geogrid, then through vibration

and rolling, the subbase is completed

4.By now, the system of geogrid can prop up kinds of construction equipment, and that construction directly above it is accepted, together with conventional manner surface

1.Unfolding the geogrid (Some fiber-material can be put under the geogrid according to the concrete condition,for example geotextile and felted cushion.)

2.Fixing it with nail or connecting with the frame of stretcher;

3.Used loader to fill with filler until it is full top and beyond of the geogrid, then through vibration

and rolling, the subbase is completed

4.By now, the system of geogrid can prop up kinds of construction equipment, and that construction directly above it is accepted, together with conventional manner surface

HDPE Geocell Technical Data

Art.NO. | Width (cm) | Length (cm) | Height (mm) | Welding Interval (mm) | Thickness (mm) | Unit Weight (g/m2 ) | Peeling Strength at Welding Point (N/mm) | Peeling Strength at Connecting (N/mm) | Yielding strength of the band (MPa) |

JRNO | 600 | 400 | 50 | 400 | 1 | 550 | 10 | 10 | 18 |

JRNO | 600 | 400 | 75 | 400 | 1 | 850 | 10 | 10 | 18 |

JRNO | 600 | 400 | 100 | 400 | 1 | 1100 | 10 | 10 | 18 |

JRNO | 600 | 400 | 150 | 400 | 1 | 1600 | 10 | 10 | 18 |

JRNO | 600 | 400 | 200 | 400 | 1 | 2200 | 10 | 10 | 18 |

Remarks: A breadth of product can be as customers' requirement, other special specification according to agreement or contract performance. | |||||||||

High Strength HDPE Geocell Technical Data

NO. | Test Item | Unit | Index |

1 | Band tensile strength | MPa | ≥200 |

2 | Tensile strength at connecting | N/cm | ≥150 |

3 | Break elongation | % | ≤15 |

| Packaging Detail:standard packing |

| Delivery Detail:within 3 working days |