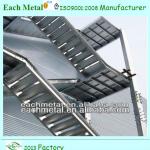

Outdoor tempered glass stair - H-1

| Type: Stairs | Place of Origin: Shandong China (Mainland) | Brand Name: DFG | Model Number: H-1 |

| Usage: Indoor | Stair Material: Tempered Glass | Stair Type: Straight Stairs | DFG experienced glass processor: Decades process experience |

| Imported famous equipment: Finland TAMGLASS tempered furnace | Min size 100*250mm: Max size 2440*4800mm | Less roller marks/good flatness: Low explosion rates under 0.2% | 3-8mm heat strengthened glass: 3-19mm tempered glass |

Dongfang glass co., ltd established in 1995, with more than 15 years processing experience.

Widely used for windows & doors, shower room, balustrade, pool fencing, skylight, furniture desktop, partition, solar panel, curtain wall, greenhouses, etc.

Tempered/toughened glass is made from annealed glass via a thermal tempering process in which the glass is heated till its softening point about 650 degrees and then quenching quickly to become Tempered glass or heat strengthened glass

Steps of Manufacturing

Step I

first and foremost the right glass combination is selected according to the clients' requirement. The choices are limitless, Clear, Tinted, low-e reflective.

Step II

The glass is then cut to size and then its edges are treated. Holes and cutouts are then drilled onto the glass. Then the glass is washed by deionized water and loaded onto the transportation bay of the furnace.

Step III

the glass is then transferred into the heating chamber of the tempering furnace. Here the glass is heated till its softening point

Step IV

The glass that comes out at the other end of the furnace is either a fully Tempered glass or heat strengthened glass depending upon the operating cycle set by the operator in accordance with the client's order

Characteristics

A fully Tempered glass is 3 to 5 times stronger than annealed glass of similar thickness. A fully Tempered glass is regarded as a safety glass and when it breaks it disintegrates into small blunt pieces/small oval-shaped pebbleswhich greatly reduce the chances of injuries

1)Strength- Fully low-e Tempered glass is generally 3 to 5 times stronger than annealed glass and twice as strong as heat strengthened glass of similar thickness, size and type. For fully Tempered glass the minimum surface compression is 10000 psi and for a heat strengthened glass is 4000-7000 psi for 6 mm glass.

2)Safety- When broken by impact, fully Tempered glass immediately disintegrates into small oval-shaped pebbles, thus greatly reducing the likelihood of cutting person

| Properties of Tempered glass | Data |

| Density (Approximate) | 2.42-2.52 g/cm³ |

| Tensile Strength | 120 to 200 N/sq.mm³ |

| Compressive Strength | 1000 N/mm2 |

| Modulus of Elasticity | 70Gpa |

| Coefficient of linear expansion | 9 x 10-6 m/Mk |

| U Value | 5.7W/m2°C for 6mm Tempered glass |

| SF for 6 mm clear | 81 % |

| SC of 6 mm clear | 0.93 |

| Selectivity | 1.0 |

| VLT of 6 mm tempered glass | 87% |

Clear Tempered glass thickness:

3mm, 3.2mm, 4mm,5mm,6mm,8mm,10mm,12mm,15mm,19mm

Color:

Clear, Ultra clear

Tinted, Grey, green, bronze, blue etc.

Reflective & low-e (including double silver low-e) etc.

Main Products we process:

a. Flat tempered/toughened glass

b. Curved tempered/toughened glass

c. Insulated glass

d. Tempered/toughened insulated glass

e. Laminated insulated glass

f. Tempered low-e insulated glass

g, Double silver low-e insulated glass

h, low-e insulated glass with TGI spacer

i. Silk screen printing glass

j. Frosted glass/land blasted glass, acid etched glass

k. Hot bent glass

Tempered glass safety corners

Holes for tempered glass door/balustrade

Non-fumigation wooden crates/Plywood crates

Production Capacity:

| Product Line Name | Production Line Capacity | Actual Units Produced(Previous Year) |

| TAMGLASS for flat Glaston for flat Northglass for curved | 360,000 SQM/Year 720,000 SQM/Year 360,000 SQM/Year | 280,000 SQM Operation in 2012 Operation in 2012 |

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

| Cutting machine | Lisec | 2 | 5 | Exceptional |

| Edge grinding machine Edge process machine | Lisec Golive | 2 5 | 5 0-5 | Exceptional Exceptional |

| Drilling machine | Ivaco | 4 | 5.0 | Exceptional |

| Tempered furnace Tempered furnace | TAMGLASS North glass | 2 1 | 5 1 | Exceptional Exceptional |

Production Flow:

Cutting

Edge finishing

Drilling

Tempering

Three factories view:

| Packaging Detail:Non-fumigation wooden crates, seaworthy crates |

| Delivery Detail:Usually 10-15 days, depends on your quantity |