mgo panel lightweight panel board - lightweight panel board 90/100/150/200mm

| Place of Origin: Hebei China (Mainland) | Brand Name: onekin lightweight panel board | Model Number: lightweight panel board 90/100/150/200mm | compressive strength: 4.4MPa |

| Sound insulation: 51dB | flexural strength: 0.492MPa | thermal transmission: 0.0349w/m.k | fire resistance: more than 3 hours |

| after-service: installation avaliable flexible | Labor efficiency: 20-30m2 per day per labor / shorten construction period | increase using space: increase 20% using space | Heat insulation: Remarkable |

| Energy saving: No asbestos, No radiation, no radioactive |

lightweight panel board introduction

lightweight panel board is a new kind of board which is manufactured from a combination of magnesium oxide and magnesium chloride as its main material.the highly purified MgO is used as the main fireproof material,fly ash and plant fiber as filling materials, the high quality MgC12 as the main cementing material to solidify other materials.

lightweight panel board Parameters

| Board size mm | Raw materials | Weight/m2 | Fireproof | Packing In full 40 ‘HQ |

| 2800*600*90 | Mgo ,Mgcl2,fiberglass/ plant fiber | 36kgs | Grade A, 3 hours | 400pcs/ 672m2 |

| 2800*600*100 | Mgo ,Mgcl2,fiberglass/ plant fiber | 40kgs | Grade A, 3 hours | 400pcs/ 672m2 |

| 2800*600*120 | Mgo ,Mgcl2,fiberglass/ plant fiber | 45kgs | Grade A, 3 hours | 300pcs/504m2 |

| 2800*600*150 | Mgo ,Mgcl2,fiberglass/ plant fiber | 53kgs | Grade A, 3 hours | 300pcs/504m2 |

| 2800*600*200 | Mgo ,Mgcl2,fiberglass/ plant fiber | 70kgs | Grade A, 3 hours | 300pcs/504m2 |

Note: Other standard size: 2900×600×90/100/120/150/200mm

Special size can be also ordered, please contact sales.

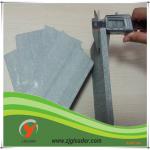

lightweight panel board Samples

lightweight panel board application

lightweight panel board installation process

lightweight panel board test data

WHY should trust onekin lightweight panel board?

1.Easy and fast installation:due to the lightweight and tongue and groove joint design, the panel can be easily installed.

2.Light weight and cost saving:1/3 of normal cement wall, saving structure and basic foundation; an experienced worker can finish 50m2/day, shortening the construction period and saving the total cost up to 20%--30%.Increase living area about 5-8% compared with traditional clay brick

3.Fireproof:rating more than 3 hours, non-combustible at 800°C, and remain flameless at 1200°C.Much better than eps cement sandwich panel.

4.Eco-friendly:100% no asbestos, no harmful substances to human body, while cement board do have asbestos.

5.With ASTM report:test results are much better than the standard. Lower cost than sandwich board

lightweight panel board Project

lightweight panel board factory

About Onekin family

1. Specialize in magnesia products, technology , machines, and some other relative products, including theMgOpartitionpanel, board, tile, door and central air conditioner pipes etc.

2. Sustainable green building system is our slogan. And our core value is“Quality primacy, High reputation, Service supremacy, Equality and mutual benefit”.

3. We have our own factory and research team for technology and products improvement; including chemical expert working in this filed for over 10 years; 15 full-time workmates including 1 building engineer and 1 mechanical engineer.

We are striving to construct a green eco earth ,will you join us ?

| Packaging Detail:lightweight panel board:Containers 40'HQ 352pcs 2800x600x100mm |

| Delivery Detail:7-20 days after prepaid |