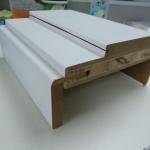

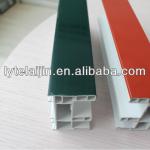

Hot sell uPVC door frames for south-east Asia countries

| Type: Door & Window Frames | Place of Origin: Henan China (Mainland) | Brand Name: LANKE | Frame Material: uPVC/Plastic |

| Color: 192 colors are available | Quality Standard: GB/T8814-2004 or as your requirements | Thickness: 2.0mm/2.2mm/2.5mm or as your requirements | Length/Piece: As you required |

| HS code: 3925200000 | Protective film: PE film with brand/logo | Usage: Window and door frames | Life: Over 30 years |

| Warranty: 10 years |

Our upvc profile usage range:

60 series for sliding window & door,

60 series for swing /tilt out window,

60 series for swing door

80 series for sliding window &door

80 series for swing door

88 series for sliding window & door

We are a upvc profile factory, mainly produce 60,80,88 series for windows & doors, meanwhile offer OEM

service for other series that popular in customers' countries.

Promised that you can enjoy the competitive price, reliable quality, best delivery and goodservice from us.

| MOQ | 10 Tons |

| 20" GP container | 10-12 Tons |

| 40" GP conatiner | 22-25 Tons |

| Payment term | T/T,L/C at sight,West Union,Escrow |

Why buy Hot sell uPVC door frames for south-east Asia countries from us?

- Honest supplier to the worldwide buyers

- Factory, direct supplier, competitive price

- Know how to control the costing with 16 years experience

- Warm and friendly service and guide

- Have experienced mould supplier for OEM profiles

- China National Standard GB/T8814-2004

- 3 shifts workers for 24hrs production, high capacity

- Small and big orders are welcome from the worldwide

Advantages of Hot sell uPVC door frames for south-east Asia countries

| 1. Special ingredient with environmental protection function, lead free,fashionable design |

| 2. Easy to install, convenient to the users |

| 3. Special design make the windows & doors look aesthetic and lighting area greatly increased. |

| 4. Excellent structure make it has various advantages, such as sound insulation, heat preservation, anti-aging, good sealing. |

| 5. Heat preservation, energy saving,it can help reduce the cost of your air conditioner |

| 6. Corrosion preventive, its widely used in costal and moist areas. |

| 7. Anti-weatherability, acid alkaline, corrosion-resistant, non-cracking, anti-pests, it will not be out of shape after using over 30 years in the areas of strong sunlight, rainstorm, blizzard. |

| 8. Excellent electricity insulation, it is much safer than metal profiles |

| 9. Fire retardant, the material burns when subject to the fire, but it does not burn by itself, it extinguishes immediately once the external fire removed. It has got a "A" class fire rating |

| 10. High precision, the deviation of the whole window dimension will be kept within ±2mm after welding. |

| 11. Firm welding, corner strength can bear the force of 3000-4000N. |

| 12. Easy to maintain and clean, the smooth surface makes the product is virtually dirt resistance, it is very easy to make it clean with soft cloth that dissolved in water. |

Testing data:

| Item No. | Inspection Item | Unit | Required Standard | Inspection Results | Pass or Not |

| 1 | Appearance | N/A | color on the visible surface must be even, surface must be smoothy and flate, no black spots on surface | Color is even, surface is smoothy and flate, no black spots | Pass |

| 2.1 | Thickness | mm | 80±0.3 | 79.9~80.1 | Pass |

| 2.2 | Width | mm | 50±0.5 | 49.8~50.2 | Pass |

| 2.3 | Straightness deviation | mm | ≤1 | 0.6 | Pass |

| 3.1 | Dimension change after heating | % | Visible wall:±2.0 Balance of two visible walls:≤0.4 | 1.6 0.2 | Pass |

| 3.2 | Status after heating at 150 ºC | N/A | No bubbles, No crack, surface smooth | No bubbles, No crack, surface smooth | Pass |

| 3.3 | Weight drop impact (drop height 1m) | pc | Broken pc≤1 | 0 | Pass |

| 3.4 | Veka softening point | ºC | ≥75 | 78 | Pass |

| 3.5 | Bending elasticity modulus | MPa | ≥2200 | 2396 | Pass |

| 3.6 | Charpy impact strength | kJ/m² | ≥600 | 918 | Pass |

Our factory BV assessment certificate and testing report:

Production Process

Factory Show:

Packing steps:

Installation

| Packaging Detail:1.Bind the profiles with plastic ropes 2.Put the binded profiles with plastic bags 3. Wrap the plastic bags with sticky tapes at both ends 4.Pack the plastic bags with packing strips firmly |

| Delivery Detail:Within 10-15 days after the deposit gets confirmed |