high quality HDPE geomembrane with textured surface - 1.0mm-3.0mm

with high coefficient of friction and function of preventing leakage specially used in anti-leakage in slope & vertical surface - details see: https://www.buildingsupplieshub.com/high-quality-hdpe-geomembrane-with-textured-surface-10057818

| Type: Geomembranes | Place of Origin: Shandong China (Mainland) | Brand Name: Jiantong | Model Number: 1.0mm-3.0mm |

| Material: HDPE,LDPE,LLDPE,PVC,EVA | Color:: white,black,red,blue and so on |

HDPE has excellent temperature property of temperature adaptability,property of welding,bearing climate,anti-erosion,anti-crack and anti-puncture.As the leakage material,therefore particularly suitable for the construction of underground,mining,landfill,sewage or dregs disposal.

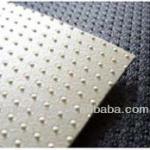

Hdpe geomembrane with textured is a new type of anti-leakage products,its one side textured and both sides textured can increase its coefficient of friction and function of preventing leakage,especially used in anti-leakage in slope and vertical surface in order to enhance its stability.

1)Material: HDPE

2Thickness: 1.0mm-3.0mm

3Width:4-8m

4Quality Inspection Standard: GB/T17643-1998, GB2 and GM

Number | value | test value | ||||||

| 0.75mm | 1.00mm | 1.25mm | 1.50mm | 2.oomm | 2.50mm | 3.00mm | ||

| 1 | Density/(g/cm2) | 0.939 | ||||||

| 2 | Tensile propeties | |||||||

| Yield strength/(N/mm) | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

| Break strength/(N/mm) | 8 | 10 | 13 | 16 | 21 | 26 | 32 | |

| Yield elongation/% | 12 | |||||||

| Break elongation/% | 100 | |||||||

| 3 | Tear resistance/N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

| 4 | Puncture/N | 200 | 267 | 333 | 400 | 534 | 667 | 800 |

| 5 | Stress crack tesistance/h | 300 | ||||||

6 | Carbon black | |||||||

| Carbon black content/% | 2.0-3.0 | |||||||

| Carbon black dispersion | Carbon black dispersion for 10 different views 9 in categories 1 or 2 and in category 3 | |||||||

7 | Oxidative induction time | |||||||

| Standard OIT | 100 | |||||||

| High pressure OIT | 400 | |||||||

8 | Oven aging at 8.5.C | |||||||

| Standard OIT-% retained after 90 days/% | 55 | |||||||

| High pressure OIT-% retained after 90 days/% | 80 | |||||||

9 | UV Resistance | |||||||

| Standard OIT retained after 1600 hrs | Not recommended since the high temperature of the Std-OIT test produces an unrealistic for some of antioxidants in the UV exposed samples | |||||||

| High pressure OIT retained after 1600 hrs | 50 | |||||||

| 10 | Low tempreture impact brittle property at-70.C | PASS | ||||||

| Packaging Detail:PP woven geotextile |

| Delivery Detail:5 days from order |