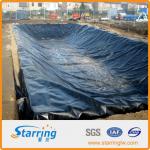

HDPE Liner for Settlement lagoon liner - HDPE

| Type: Geomembranes | Place of Origin: Shandong China (Mainland) | Brand Name: Starring | Model Number: HDPE |

| Material: HDPE | Width: Max 8 meters | Length: 50-100m | Thickness: 0.3-3.0mm |

| Standard: ASTM and GB | Sample: Free sample |

HDPE Liner for Settlement lagoon liner

Product Description

The HDPE Lineris a waterproof membrane made by polyethylene (PE), PVC ,After the processes of calendering, spreading

Widely used in the engineerings such as landfill,sewage & waste residue processing plant,dam,tunnel,building,traffic and environmental protection,etc

Application Range

1.Environmental protection, sanitation (such as landfill, waste water treatment, toxic and harmful chemicals disposal sites, storage of dangerous goods, industrial waste, construction and demolition waste, etc.)

2. Water (such as impervious, stop water loss, and reinforcing of lakes, and the impervious, slope protection, etc.)

3.Municipal projects (underground subway, engineering underground and reservoirs on the roof, and the park on the roof, the lining in the sewage pipes, etc)

4.Garden (artificial lakes, ponds, the lining of tank in golf course, slope protection, etc)

5.petrochemical (chemical plants, oil refineries, oil tank of fill stations, chemical reactions pond, the lining of settling basin, second lining, etc)

6.Mining (washing and selecting pool, heap pool, ashery, dissolving pool, settling basin, stock dump, lining of tailing pond, etc)

7.Agriculture (reservoirs, drinking water tank, water storage pond, irrigation systems)

8.Aquaculture (fish ponds, the lining of breeding shrimp tank, slope protection of sea slug tank)

9.Salt industry (crystallization pond, thatch or plastic thatch of salt pond, salt membrane)

Product Features

1) Good physical and mechanic performance

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

4) Good adaptability to high and low temperature, non-toxicity, long service life

5) Good waterproof, drainage, anti-seepage and damp proof effects

6) Complete width and thickness specifications, low cost and easy installation.

Technical Parameter

No. | Item | Test Value | ||||||

| 0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | ||

| 1 | Minimum Density(g/cm³) | 0.939 | ||||||

| 2 | Tensile Property | |||||||

| Strength at yield,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | |

| Strength at break ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | |

| Elongation at yield,% | 12 | |||||||

| Elongation at break,% | 700 | |||||||

| 3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 |

| 4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 |

| 5 | Stress Crack Resistance, hrs | 300 | ||||||

| 6 | Carbon Black | |||||||

| Carbon Black Content, % | 2.0-3.0 | |||||||

| Carbon Black Dispersion | 1 or 2 | |||||||

| 7 | Oxidation Induction Time(OTI) | |||||||

| Standard OTI Min | 100 | |||||||

| High Pressure OTI Min | 400 | |||||||

| 8 | Impact Cold Crack at -70°C | Pass | ||||||

| 9 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-16 | ||||||

| 10 | Dimensional Stability (%) | ±2 | ||||||

Production Line

Method of Construction

Any other questions, please feel free to contact us.

| Packaging Detail:PE film or Woven bags |

| Delivery Detail:Within 15 days |