Gold Laser Plum Blossom (Black Backing) aluminium composite panel - SF3102-GAL

| Place of Origin: Guangdong China (Mainland) | Brand Name: AULAND | Model Number: SF3102-GAL | Usage: Indoor |

| Function: Fireproof | Surface Treatment: Film Laminated | Color and pattern: Black Horizontal Strips (laser), other designs available | Panel thickness: typically 1mm, 2mm, 3mm; other thicknesses available on request |

| Plastic core material: re-cycled or natural polyethylene resin, fire retardant material | Aluminum thickness: 0.1mm to 0.5mm | Panel sizes: typically 1220x2440mm, other lengths available on request | Other designs options: black curve lines (laser),white stars (laser) etc |

| Applications: interior wall, kitchen room, decorative backdrop, cabinet cover | Technical Compliances: ASTM standards, national standard GB/T 17748 |

Aluminum Coated with Laser Effect Series Aluminum Composite Panels

Aluminum Coated with laser effect series aluminimum composite panels are designed to provide attractive high tech and glamorous outlook required by interior designers. There are versatile choices of different electroplated designs available for selections, including white curve line, white star, white river line, white horizontal strips, white butterfiles laser etc. This product series is one of the main product series of Auland composite panels.

Wide Applications

Auland decorative panels has been designed to fulfill the robust structural requirement as well as providing alternatives to interior designers for creating their masterpiece. They are widely used in various applications, such as cladding, partitioning board, indoor decorative wall, cabinet cover, signage board, exterior wall, ceilings, decorative door etc.

Other Series

Apart from crown series, there are other product series available from us, including PVDF series for outdoor decoration, Polyester painted series for colorful indoor decoration, Wood or Marble alike film laminated series, High gloss pearly bright colorful film laminated series for indoor decoration, pre-anodized series for high reflection decorative requirement, marble/wood alike PVDF coated series for outdoor patterned decoration etc.

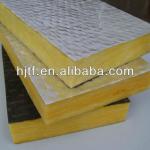

Product Construction

The product is composed of plastic core of polyethylene laminated at both sides by skins of 0.5mm or less aluminum sheets. There are different choices of surface aluminum available. We provide PVDF coated skin, polyester painted skin, pre-anodized surface skin, marble/wooden patterned coated skin etc. Meanwhile, we also provide more options by using film lamination on the surface aluminum.

Technical Data

Our product are designed and manufactured to meet the international standards, including:

Tensile and Yield Strength ASTM 638

Bending Strength ASTM 790

Shearing Strength ASTM 732

Adhesive Peel Off Strength ASTM 903

Wind Pressure Resistance ASTM 330

Impact Resistance AAMA 2605

Abrasion Resistance ASTM D 968

Color Retention ASTM D 2244 - 93

Chalk Resistance ASTM D 4214 - 89

Gloss Retention ASTM D 523 - 89

Corrosion Resistance ASTM B 244

Fire Resistance DIN 4102 Class B1

etc

Easy to Maintain

Auland aluminimum composite panels are easy to use. During installation, saw cutting, shear cutting, grooving, punching, perforating, drilling are possible by deploying common metalwork and woodwork machines. Bending and folding are done by grooving the back skin using router or trimmer.

Seaworthy Packing

There are two typical packing method for container loading:

a. The panels can be loaded and stacked firmly together inside the containers with overall wooden and metal frame support to ensure no movement within the container during sea transportation. Re-enforced iron tapes are used to hold the stacked panels together.

b. Another option is to pack 100-300 panels into pallets, firmly hold them together using re-enforced iron tape and then stored the pallet into wooden box before loading into the containers. Additional enforcement structure will be added inside the container to avoid movement of boxes during transportation when required

| Packaging Detail:There are two typical packing method for container loading: a.The panels can be loaded and stacked firmly together inside the containers with overall wooden and metal frame support to ensure no movement within the container during sea transportation. Re-enforced iron tapes are used to hold the stacked panels together. b.Another option is to pack 100-300 panels into pallets, firmly hold them together using re-enforced iron tape and then stored the pallet into wooden box before loading into the container. |

| Delivery Detail:25 days |