GCL for waste landfill geosynthetic clay liner with hdpe geomembrane - hy

| Type: Other Earthwork Products | Place of Origin: Shandong China (Mainland) | Brand Name: haoyang | Model Number: hy |

| layer: 4 | first layer: ldpe geomembrane | second layer: PP or PET nonwoven geotextile | third layer: bentonite |

| forth layer: PP woven geotextile |

geosynthetic clay liner with hdpe geomembrane

1.1~6 m,2800g~7000g/m2

2.ASTM D test

3.Waste Landfill;Oil Pollution Prevention;Agriculture

Factory:We are the manufacturer,geotextile,geomembrane,composite geomembrane,woven geotextile,GCL, triplanar geocomposite,waterproof membrane,PP short fiber, geogrid, geobag,geoweb,geocell, geonet,and so on geosynthetics.

Certificate:ISO9001;ISO14001

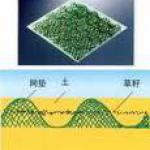

1.GCL products introduction

Bentonite mineralogy name is montmorillonite, natural bentonite according to the main chemical composition is divided into Na- and Ca- two broad categories. Bentonite with the characteristics of expansion with water,the general expansion of the Ca-bentonite, the expansion only about three times of its own volume; And Na-bentonite expansion, its volume is about 15 times, absorbing 6 times its own weight water, this expansion of bentonite formed by high-density gel with the performance of the exclusion of water.Make use of this performance, people take this Na-bentonite material used for waterproofing. To facilitate the construction and transportation, will be locked the bentonite in two geosynthetics middle layer, to protect and reinforce the GCL has a shear strength.

2. Manufacture method

GCL by high inflated Na-bentonite filled in a special compound geotextile and non-woven geotextile, from the top of the non-woven geotextile through a special needle punched method to lock the bentonite in the lower compound geotextile made of carpet-like fabric. Needles punched method bentonite geosynthetic clay liner could be the formation of many small pad of fiber space, bentonite particles can not move, at the pad with water to form a high density of the jelly evenly waterproof layer and effective to prevent water seepage.

3.Application

1) Rubbish filling landfill sealing up treatment project

2) Water scene project and artifical scene project

3) Underground tanker project

4) Reservoir (pool) impervious project

5) Canal antiseepage project

6) Subway project

7) Tunnel project

8) Underground structure and underground base waterproof project

4. Waterproof characteristics

1) Density:Na-bentonite under water pressure form high density diaphragm, when the thickness about 3mm, its permeability coefficient is less than αx10-11 m/sec, is 100 times of 30cm of clay, has a strong self-protection properties of water.

2) Have a permanent water-proof performance:Because Na-bentonite base for natural inorganic materials, after a long time or a change in the environment, aging or corrosion does not occur, therefore, durable waterproof performance.

3) Simple operation, short construction period: Compare to other waterproof material, the construction is relatively simple and does not need heating and paste. Just need bentonite powder and nails washers for connect fixed etc.

4) From the effects of temperature: In the cold weather will not be brittle fracture.

5) Waterproof materials and the target of integration: Na-bentonite and water reaction, with 13-16 times expansion capacity, even if the concrete structure vibration and settlement occurred, bentonite in GCL can repaire within 2mm concrete surface cracks.

6) Green environmental protection: Bentonite for natural inorganic materials, non-toxic harmless to humans, does not effect to the environment, has a good environmental performance.

5.Procution size

Thickness 6mm,roll width≤6m roll length is 50 m (or customers designate)

6.

Bentonite geosynthetic clay liner GCL category and physical indicators

| Number | Property | National standard JG/T 193-2006 | Enterprise Standard | Inspection standards |

| 1 | Geosynthetic Clay Expansion index | ≥24 ml/2g | ≥25ml/2g | ASTM D5890 |

| 2 | Mass Per Unit Area(g/m2) | ≥4800 g/m2 | ≥4800 gm2 | ASTM D5993 |

| 3 | Tensile Strength | ≥6KN/m | ≥8KN/m | ASTM 4632 |

| 4 | Maximum load elongation | ≥10% | ≥10% | ASTM 4632 |

| 5 | Permeability | ≤5×10-9 | ≤5×10-9 | ASTM D5084 |

| 6 | Moisture content | ≤15% | ≤15% | ASTM D4643 |

| 7 | Peel strength | ≥40N | ≥60N | ASTM D4632 |

| 8 | Hydrostatic pressure | 0.4Mp | 0.4~0.6Mp | ASTM D5891 |

7. geosynthetic clay liner with hdpe geomembrane physical indicators:

Bentonite swell Index: ≥24Ml/2g

Bentonite mass≥3600g/m2

Peel Strength of GCL(for geotextile componant)≥600N/M

Peel strength of GCL(for geomembrance component)≥300N/M

Grab strength≥600N

Mass of Non-Woven geotextile≥200G/M2

Mass of Woven Geotexile≥110G/M2

HDPE thickness ≥0.1MM

Details:

The GCL used for Waste Landfill and other projects.

GCL samples of plain weave woven fabric type

Liner of Oil Pollution Prevention.

The Oil Pollution Prevention Liner is a new type of environmentally friendly products,it doesn’t only have the good characteristics of ordinary GCL. But also can absorb oils,heavy metals ions and other pollutants,it can protect the soil and reduce sources of pollution.

Details show of the product

| Packaging Detail:roll |

| Delivery Detail:35days |