| steel stair tread CHN - YB/T4001-1998

USA - ANSI/NAAMMMBG531-88

ENGLAND - BS4592-1987

AUSTRALIA - AS1657-1992

Steel Standard: CHN - GB700-88

Hot Galvanized Standard: CHN - GB/T13912-92 | no anti-slip requirement for welding ladder stringers Characteristics the type of steel grating which pitch of bars is30mmis used most widely for all sectors of industry. It has the greates resistance to surface inpact. | | anti-slip requirement for welding ladder stringers the type of steel grating which pitch of bars is40mmis widely used in the industry field too. For the suitable interval of the bars so it always economical and weight-lightest. | | no anti-slip requirement for connecting with ladder bolt the type of steel grating which with pitch of bars is60mm, cross bars pitch 50mm has been developed specially for mining industry and weight-lightest in all grating. In case of short spans they can meet a variety of uses. | | anti-slip requirement for connecting with ladder bolt 1>High strength and light structure 2>Powerful anti-corrosion,durable and long working life 3>Beautiful appearance,bright surface 4>No dirt-rain-snow deposit,automatic cleaning,easy maintenance 5>Good ventilation,day-lighting,heat-dispersing,resistant to sliding and explosion. 6>Easy installation and disassembly |

material

| Bearing bar centers at 20mm: This kind of fine mesh steel gratings have strong load ability and also can prevent the access of sundries of 18mm in diameter. This kind of gratings fit for pedestrian deck, walkway and ditch covers which require high security Notes: common welding standard: single-side full welding every 6 bearing bars | | Bearing bar centers at 30mm: This kind of steel grating is the most commonly used in projects with American, Australian, Japan standards are available. This kind of gratings are featured well by heavyduty, well resistance of strong impact on surface. this kind of steel grating fit for all kind ofindustrial platforms. Notes: common welding standard: single- side full welding every 5 bearing bars |

| Bearing bar centers at 40mm: light grating and very economical. This kind of gratings fit for fixed platforms, walkway, and stair treads and British, German,French and Japanese standards are available. The products most commonly used for Belt corridor, storage shelf,Attic panel, trestle, guardrail, sunshade gate, etc. notes: common welding standard: single- side full welding every 4 bearing bars | | Bearing bar centers at 60mm: This kind of steel gratings are especially used for mining industries. It can solve the problem that mineral splashing down and stacks on the walkway. This product usually used for mineral miningand processing and it is the best choice for workshop, meeting room and suspended ceiling of stadium in terms of it's light weight. notes:common welding standard: single- side full welding every 3 bearing bars |

| Hot-dip galvanizing plant the company has 1500square meters,with 8.5 meterslong X 1.6meters wide X deep 2 meters large zinc pot.has variety of species galvanized steel work pieces,steel grating/communications tower, a lighthouse ,sign posts,anchor chain ,highway guardrail ,ship fittings ,pipe and so on. the features of hot-galvanizing Uniform plating coat with high surface finish.Adhesiveness and strong resistance to corrosion Wide-Applications of Hot Galvanizing Anti-corrosion treatment for iron tower of various power transmittinglines,steel-pipe towers,,communication iron towers,lamp posts and lamps, steel bar gratings,guard rails of highways,and all kinds of steel mambers,together with all kinds of metal surface Advantage Light weight High strength Great load-bearing capacity Economic cost Ventilation and light admission Modern fashion and attractive appearance Non-slip and safety Easy cleaning and installation Durability | |

remark We have the automatic machine to make steel grating with largest production capability and high production speed

Twist steel cold dial the straightening machine Steel grid plate automatic cutting bar machine Our projects

| This is our project of steel grating ,it can be used to many aspects just like: | | platform | trestle | trend | fence | equipment walk way | | pavement | channel over | manhole cover | trash rack | mentance platform | | foot bridge | scaffold | ladder | storage shelf | marine platfor |

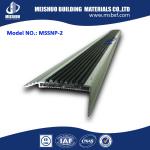

Installation of steel grating: 1.Welding & using saddle clips are two ways for installation of grating. The welding is suitable for those places where there is no need to move or dismental,for instance,the flooring around the machines. However,using saddle clips are featuring in easy installation & saving zinc layer. 2.Regarding welding installation, angle wolding would used at the first bearing bar of every corner,which the welding length is no less than 20mm,&the height is no less than 3mm. 3.Saddle clip composed of a top plate,a hold down & a M8 bolt, is suitable for all kinds of steel gratings installation. 4.Regarding saddle clip installation, at laest four sets of saddle clips would be used in one pc grating.It would be better using more in the staddle for those gratings with a bigger span. Application

packing

Qingdao Zhizhen Steel Grating Co.,Ltd is the subsidiary of Qingdao Yili Steel Structure Co.,Ltd,havving anumber of higly qualified technical and management personneladvanced management and strong technical force Steel grating standards:

A) China: YB/T4001-2007

B) USA: ANSI/NAAMM (MBG531-88)

C) UK: BS4592-1987

D) Australia: AS1657-1985

E) Japan: JJS How to order 1.Bearing Bars center to center and cross bars center to center 2.Depth & thickness of bearing bars 3.Surface:serrated or smooth 4.Dimensions of area 5.Span(direction of bearing bars) 6.Finish: mill,hot dip galvanized 7.banding or no banding

|