galvanized metal corner bead(15years factory) - NF-AB-014

| Place of Origin: Guangdong China (Mainland) | Brand Name: NianFa | Model Number: NF-AB-014 | Material: Stainless Steel,stainless steel |

| Thicknes: 0.3mm-0.5mm | length: 3.0m | Width: 25x25,45x45,60x60mm . | color: silver |

| Applications: Building Materials | type: Expanded metal,Perforated meal | certificate: ISO9001:2008 | Delivery Time: 15-20days |

| production experience: 15 years |

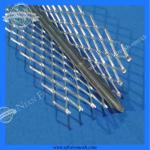

galvanized metal corner bead

Character:

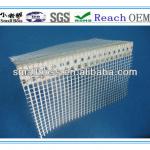

The expanded mesh wings provide great strength to support and protect the wall corner in construction.

Type:expanded corner bead, corner bead with reinforce flange, corner bead with creased reinforce flange, corner mesh, perforated corner bead, movement bead, plaster stop bead.

Specification

| Width(mm) | Thicknes (mm) | Max Length (m) |

| 60x60 | 0.3-0.5 | 3/2.5 |

| 32x32 | 03-0.5 | 3/2.5 |

| 50x50 | 0.3-0.5 | 3/2.5 |

| 45x45 | 0.3-0.5 | 3/2.5 |

| 30x30 | 0.3-0.5 | 3/2.5 |

| (Selvage)60x60 | 0.3-0.5 | 3/2.5 |

| (Selvage)32x32 | 0.3-0.5 | 3/2.5 |

| (Hole)25x25 | 0.3-0.5 | 3/2.5 |

| (Hole)32x32 | 0.3-0.5 | 3/2.5 |

Wealso can do the type as the client's request.

We promise 100% check the goods before loading.

Other thickness and length is available to order.

uses:

it helps toprovide a straight arris for better finishing. the expanded wings provide a good anchorage for most types of plaster nails, at 600mm centers along both sides of wings. render coat is applied just below the nosing. the exposed nosing can be painted over with emulsion paint.

The installation of galvanized metal corner bead

The first stepof its installation is measuring and cutting the corner bead to length. The corner bead although not forced to fit, must span the entire length of the projected corner less approximately ¼ inch. This gap, small enough to be unnoticed by a stucco mortar applicator, is an insurance in case the structure settles before mortar application.

Sincethey are produced in maximum lengths of 3 m (10 ft.), any projected corner longer than 3 m (10 ft.) re-quires at least two corner beads. The installation of corner beads to long corners is made easier through the use of a plumb line.

Using pre installed benchmarks such as stucco stop, control joints, or wood trim, tack in the corner bead, with a few nails. Sight down both planes of the corner bead and make sure that the projecting edge is straight.

Move the projecting edge of the corner bead by either lightly tap with a hammer, or pushing the corner bead using nails angled in the direction that the bead must move. When the projected edge of concern is the correct distance from the backing in both planes, tack it in place. Continue to straighten the corner bead until it is straight in both planes, and held firmly in place.

The trick to installing straight corner bead, without a plumb line, is to continually move different segments of the corner beads projected edge to that segments correct straightened position. Begin by using nails to divide the bead into to two large sections, and then continually dividing these sections into smaller sections, until the distance between nails is approximately 15 cm (6 inches).

The corner bead must be held firm and rigid enough to resist movement or damage caused by the application of the stucco mortar.

Detail of product

| Packaging Detail:Supplied in a cardboard dispenser, 10 or 20 rolls per pack |

| Delivery Detail:within 15-20days after received your order |