Film Faced Plywood/Shuttering Plywood/Construction Plywood /Panels - CH-1401

| Type: Plywoods | Place of Origin: Shandong China (Mainland) | Brand Name: Chaosheng | Model Number: CH-1401 |

| Usage: Outdoor | Grade: First-Class | Main Material: Poplar | Formaldehyde Emission Standards: E2 |

| Plywood Type: 5-15Ply Boards | Moisture: 10%-14% | Thickness: 9mm~21mm | Thickness tolerance: +/-0.3~0.5mm |

| Size: 1220x2440mm, 1250x2500mm, 915x1830mm | Face and Back: Black, Brown or Red Film | Film Gram: 240g/m2 (black film), 120g/m2 (brown film) | Edge Treatment: Sealed by waterproof paint |

| Glue: MR, Melamine or WBP | Density: 500~680kg/m3 | Water Absorption: ≤10% |

Specifications

Film Faced Plywood

1)Film: Black, Brown and Red

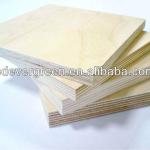

2)Core: Poplar/Hardwood/Birch/Eucalyptus/combi, etc.

3)Size: 1220x2440mm, 1250x2500mm, 915x1830mm, 1200*2400mm

4)Thickness: 9mm, 10mm, 12mm, 15mm, 18mm, 20mm, 21mm

Standard export pallet packing: (1) Inner packing: pallet is wrapped with a plastic bag (2) Outer packing: pallet is covered with plywood or carton and then PVC/steel tapes for strength

Within 15 days after receiving the deposit or L/C

| Product Name | Film Faced Plywood/Shuttering Plywood/Construction Plywood /Panels | |||

| Size | 1220x2440mm, 1250x2500mm, 915x1830mm or as clients requirement | |||

| Thickness | 9mm, 10mm, 12mm, 15mm, 18mm, 21mm | |||

| Thickness Tolerance | +/-0.3~0.5mm | |||

| Face/Back | National Film (Black, Brown and Red), imported Dynea Brown Film or anti-slip surface (Black or Brown) | |||

| Film Gram | 240g/m2 (Black and Red Film), 120g/m2 (Brown Film) | |||

| Core | Poplar, Hardwood, Eucalyptus, Birch, Pine, combi, etc. | |||

| Joint Way of The Core | Overlap joint, end joint, scarf joint or finger joint | |||

| Edge Treatment | Sealed by waterproof painting | |||

| Glue | MR, Melamine or WBP | |||

| Grade | A grade or as clients requirement | |||

| Density | 500~680kg/m3 | |||

Technical Parameters | Moisture Content | 10%~15% | ||

| Water Absorption | ≤10% | |||

| Modulus of Elasticity | ≥5000Mpa | |||

| Static Bending Strength | ≥30Mpa | |||

| Surface Bonding Strength | ≥1.60Mpa | |||

| Internal Bonding Strength | ≥0.90Mpa | |||

Screw Holding Ability | Face | ≥1900N | ||

Edge | ≥1200N | |||

| Usage & Performance | Film faced plywood is widely used for construction concrete formwork. It has many advantages compared with iron formwork. The advantages are as below: 1. The biggest size of the film faced plywood is 1250x2500mm, which could decrease the number of the joints and increase the working efficiency. 2. Light weight, It's more suitable for high-rise building and bridge construction. 3. It can be used for many times if used and stocked correctly, which can save the cost greatly. 4. It can keep the surface smooth and beautiful when used for pouring, and you don't need to plaster the wall for second time, as it can decorate directly that can decrease the construction period 30%. 5. It will not pollute the surface of the concrete, but iron formwork has the disadvantages of rusty and erosive, etc. 6. It is good for construction in winter that it can be used as template for curved surface. 7. It is better than bamboo Plywood and small steel panel in terms of nailing, sawing and drilling. It can be processed to template with all shapes according to needs. | |||

Packing | Standard Export Pallets | Inner Packing | Pallet is wrapped with a plastic bag | |

| Outer Packing | Pallet is covered with plywood or carton and then PVC/steel tapes for strength | |||

Loading Quantity | 20’GP | 8pallets/22cbm | ||

| 40’GP | 16pallets/42cbm | |||

| 40’HQ | 18pallets/53cbm | |||

| MOQ | 1x20’FCL | |||

| Supply Ability | 2000cbm/month | |||

| Payment Terms | T/T 30% prepaid and 70% against the copy or fax of BL. or irrevocable L/C at sight | |||

| Delivery Time | Within 15 days after receiving deposit or original L/C | |||

| Certification | ISO9001:2000, CE | |||

Any question pls do not hesitated to reach me!

Michelle

Skype: kayljf78

QQ:459470462

Cell: 0086-13053987363

| Packaging Detail:Standard export pallet packing(1) Inner packing: pallet is wrapped with a plastic bag (2) Outer packing: pallet is covered with plywood or carton and then PVC/steel tapes for strength |

| Delivery Detail:Within 15 days after receiving the deposit or original L/C |