Fiberglass thermal Insulation duct Wrap batt /Low density glass wool felt thermal insulation - YG-FGW13

| Type: Other Heat Insulation Materials | Place of Origin: Hebei China (Mainland) | Brand Name: YG | Model Number: YG-FGW13 |

Fiberglass thermalInsulationductWrap batt /Low densityglasswoolfelt thermalinsulation

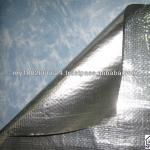

Adapting the advanced centrifugal blowing process, our Company produces glass wool blanket rolls that is soft, fine, waterproof and fireproof with good rebound elasticity (veneering like reinforced aluminum foil can be applied), providing an ideal heat preservation and sound absorption material for steel structure constructions. This product has the characteristics of good heat preservation and sound absorption, low construction cost, short cycle of works, nontoxicity, non-stimulation to the skin, guarantee to worker’s health and fine appearance.

Main indexes of physical properties of centrifugal glass wool

| Item | Unit | Index | Standard |

| Density | kg/m3 | 10-100 | GB/T 5480.3-1985 |

| Average fiber dia. | µm | 5.5 | GB/T 5480.4-1985 |

| Water content | % | ≤1 | GB/T 3007-1982 |

| Grade of combustibility | Non-combustible Grade A | GB 8624-1997 | |

| Reshrinking temp | °C | ≥250 | GB/T 11835-1998 |

| Thermal conductibility | w/m.k | 0.038-0.06 | GB/T 10294-1988 |

| Hydrophobicity | % | ≥98.2 | GB/T 10299-1988 |

| Moisture rate | % | ≤5 | GB/T 16401-1986 |

| Sound absorption coefficient | 1.03 product reverberation method 24kg/m32000HZ | GBJ 47-83 | |

| Slag inclusion content | % | ≤0.3 |

Product specification and type:

| Product | Length(mm) | Width(Diameter)(mm) | Thickness(mm) | Density(kg/m3) |

| Boards | 1200-2400 | 600-1200 | 20-100 | 24-96 |

| Blanket | 11000,2000 | 1200 | 25-150 | 12,16,20,24,32,40,48 |

| Batt | 1160-1200 | 410-610 | 100-200 | 10-48 |

Glasswool is manufactured via the centrifugal ROTARY PROCESS after fusing quartz sand and other raw materials in a high temperature. Our products are provided with top-level equipments and perfect facilities of various types for testing and inspection. All technical qualifications of our products can fully satisfy the requirements set by the National standard GB/T13350-92. It is doing well to energy saving, efficiency improvement, environment protection and comfort ability improvement.

Glasswool felt wrapped with two types of face and no face. It is specially designed for business building, organization building, the hollow wall of industrial and agricultural buildings as well as the sound absorbing and temperature keeping and heat insulate processing. Standard Specification:

Unit Weight (kg/m 3 )

10 \ 12 \ 14 \ 16 \ 20 \ 24 \ 32

Thickness (mm )

25 \ 30 \ 40 \ 50 \ 75 \ 100

Size (mm )1200*10 -20M

Glasswool board is in rectangle with many choices of unit weight. The heat insulation materials are usually using "2b" centrifugal glass temperature keeping board, the average diameter of fibre is around 7 micron with the types of faced or no face for all. With the features of light, wear and tear resistance and tenacity, it satisfies the heat insulation requirements. It can save the energy, reduce heating wastage and cut the cost, if build it correctly, the transmission of sound wave can be reduced effectively. It is the unearthly sound absorbing and warm keeping material. It has been widely applied for heat insulation of house wall, compartment; Temperature keeping of computer rooms, refrigerator; Denoise of power plants and pump rooms; Adjustment of Hi-fi etc. Standard Specification:

Unit Weight (kg/m 3)

24 \ 32 \ 40 \ 48 \ 56 \ 64 \ 80 \ 96

Thickness (mm)

15 \ 20 \ 25 \ 30 \ 40 \ 50 \ 75 \ 100

Size (mm)1200*600

Glasswool pipe shell is antisepsis, non moisture absorption, no smiley, no moldy with no germs propagation. The materials are suitable for temperature keeping of heat pipes, cooling pipes, hidden and outside pipes. It has passed the all the indexes of incombustible materials in standard GB/T5464-1999. Effectively prevent the cooling, pipe freezing and pipe noise controlling by using the thickness and surface materials with attention in the sealed processing between joints. Standard Specification:

Unit Weight (kg/m 3) 50 \ 64

Thickness (mm) 25-100

Diameter (mm) (Inch) 22-425(1/2"-18")

Length (mm) 1000

Product specifications:

| density(kg/m3) | width(mm) | thickness(mm) | length(mm) | packing/roll | |

| 10-48 | 600 | 25-200 | 5-30 | 2roll | |

| 10-48 | 1100 | 25-200 | 5-30 | 1roll | two-roll overlapping |

| 10-48 | 1150 | 25-200 | 5-30 | 1roll | two-roll overlapping |

| 10-48 | 1200 | 25-200 | 5-30 | 1roll | two-roll overlapping |

| 10-48 | 1250 | 25-200 | 5-30 | 1roll | two-roll overlapping |

Technique data:

| Item | Unit | Specification |

| Average diameter of fiber | um | ≤8 |

| Density | Kg/m3 | 10-100 |

| Thermal conductivity | w/m.k | 0.030-0.044 |

| Inflammable property | Non-inflammable | |

| Hydrophobic coefficient | % | ≥98 |

| Service temperature | °C | -120-400 |

| Slag ball | % | ≤0.3 |

| Organism | % | ≤4 |

| Water | % | ≤1.0 |

| Water absorption coefficient | % | ≤1.5 |

| Packaging Detail:with plastic film and weaving bags outside or as per request |

| Delivery Detail:within 3-5 days once we receive the deposit |