Fiberglass Ceiling Panels - ERXFRP-014

| Type: Ceiling Tiles | Place of Origin: Tianjin China (Mainland) | Brand Name: TJERX | Model Number: ERXFRP-014 |

| Color:: White,or as customized | Port:: Tianjin,(China Mainland) | Dimensions:: 750, 840, 820, 980, 950, 900, 475, 760, 1m-2 | Lifetime:: 12-15 years |

| Fibre glass:: >30% | Resin:: Phenylene UP resin | Thickness:: 0.8mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm | Transmittance:: 75%±2% (jewel blue) 53%±2% (milky white) |

| Thermal transmittance:: 70%(light blue),62%(milky) | Heat limits:: -60℃ to 130℃ |

Fiberglass Ceiling Panels Specifications:

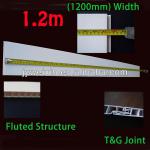

1) Thickness: 0.8mm-3.0mm;

2) Width: Max. 2100mm;

3) Length: any dimensions (5800mm & 11800mm to be loaded into the container)

4) Color: white or as customized

Special specification and color is also available.

Fiberglass Ceiling Panels Technical Data:

FRP roof sheet is bright and clean appearance, light weight and high performance, high light transmittance,

anti-corrosion.

Mechanical properties: High rigid and high tenacity FRP Sheet.

Resin Ingredient: DIC FHH-1092 high quality additive fireproofing resin.

Fiber Intensity: Non-alkali, non-twist, non-glue fiberglass.

Surface Treatment: Application of PT055 film over both sides surface.

Reinforced Line: Tensile reinforced lines with longitudinal uniform distribution (It depends on consumers to choose voluntarily whether adding)

Fiberglass: high-quality fiberglass, the content being no less than 30%.

Unit Weight: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness: 0.8 mm 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm

Temperature resistance: -60C to +130C

Light Transmittance: 75%±2% (jewel blue) 53%±2% (milky white)

Anti- ultraviolet Rate: 97% (adding more than 0.25% UV absorbent)

Cracking Elongation Rate: 1.9%

Thermal Expansion Coefficient: 2.3×10-5cm/cm/C

Thermal Conductivity: 0.18w/m.k

Warranty: 12-15 years

Comparison:

Contrast between FRP and Other Materials window&door

| Wood | Easy to manufacture but susceptible to tarnishing, damage vegetation. It have been eliminated. |

| Aluminum alloy | Beautiful appearance, easy to process, high intensity. But it is a good conductor of heat, wastes energy and non –corrosion, restricted use in developmented countries. |

| PVC | Low thermal conductivity good corrosion resistance easy to manufacture, but in high temperature easy to transfigure, low intensity. |

| FRP | Excellent corrosion resistance, good insulation and security. FRP section is the best building material now. |

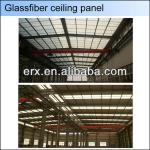

Fiberglass Ceiling Panels Applications:

1) Unusual decorations, corridors and pavilions in gardens and recreational and rest places;

2) Interior and exterior decorations of commercial buildings, and curtain walls of the modern urban buildings;

3) The transparent containers, front wind shields of motorcycles, airplanes, trains, ships, vehicles, motor boats, sub marines;

4) Telephone booths, street name plates and sign boards;

5) Instrument and war industries - windscreens, army shields

6) Walls, roofs, windows, screens and other high quality indoor decoration materials;

7) Sound insulation shields on express ways and city overhead highways;

Business Subjects:

1.Payment Terms:

1).T/T:30% Deposit,70%at B/L Copy sight.

2).L/C

3).T/T+L/C

If you are interested, please kindly offer:

1.Thickness, width, quantity

2.Delivery Time

3.Packing you want.

Manufacturing Process:

Fiberglass Ceiling Panels Project Examples:

| Packaging Detail:Seaworthy or as customized |

| Delivery Detail:15-25 days after deposit |