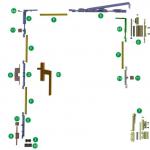

extruded aluminum window frame - SG

1.Material:6063,6061,6060, 2.Surface:anodized,mill finish,powder coated, 3.Product warranty 15 years, 4.Competitive price - details see: https://www.buildingsupplieshub.com/extruded-aluminum-window-frame-10057024

| Place of Origin: Jiangsu China (Mainland) | Brand Name: Lutong | Model Number: SG | Frame Material: Aluminum Alloy |

| Open Style: Sliding | Type: Sliding Windows | Opening Pattern: Vertical | Surface treatment: mill finish,anodizing,powder coated |

| Color: silver,black,green,blue,yellow | Wall thickness: above0.5mm | Deep process: cutting,drilling,punching | Certification: ISO9001:2008;ISO14001:2004;SGS |

1.Specification

| Material | 6063,6060,6061,6005 |

| Temper | T4,T5,T6 |

| Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated,Wooden Finish,Polish |

| Colour | Silver,Black,Red,Blue,White,and many other colors can be available |

| Length | as required |

| Shape | Square,T-slot,or as per the drawings and samples |

| Fabrication | cutting,drilling,punching,milling,durring,etc |

| Wall thickness | above .5mm |

| Package | inner plastic paper interleaving each piece profile,outer fixed by plywood or pallets, or as per your requirements |

| Payment terms | TT or LC at sight |

| Delivery time | 10-12 days after order confirmation |

| Certification | ISO 9001:2008;ISO14001:2004;SGS |

| Warranty | 15 years |

| Type | Aluminum casement window/Aluminium sliding window/Aluminium hinges window/Aluminium top hung window/Auminium tilt&turn window/Aluminium shutter window |

| Capacity | 3000 tons per month |

2.Primary Technical Data

1) Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

| 6061 | 0.4-0.8 | 0.70 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

| 6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.4-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

2)Mechanical property

| Alloy | Temper | Tensile strength | Yield strength | Elongation |

| 6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

| T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% |

3)Anodized

Grade | Anodizing thickness | Hole scaling quality of oxide layer | |

| Average thickness | Local thickness | P. Cr acid-erosion weight less method | |

| AA10 | ≥10um | ≥8um | ≤30 mg/d m2 |

| AA15 | ≥15um | ≥12um | |

4)Powder coating & wooden-grained

| Coating thickness | Coating impress rigidity | Adhesive force of coating layer |

| 40-120um | Indentation hardness>80 | 0 grade |

3.Our advantages

1)Engineering design and support.

2)Aluminium profiles deeply processing:cutting,punching,drilling,milling,and fabricating.

3)High Quality system, strictly inspection during production and whole inspection before package.

4)Good performance, product warranty for 15 years.

4.Factory show

5.Packages and Loading

| Packaging Detail:inner plastic paper interleaving each piece profile,outer fixed and protected by plywood or pallets;usually 12 tons for a 20 feet contaner,24 tons for a 40 feet container |

| Delivery Detail:10-12 days after order confirmation |