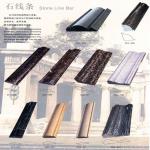

Exterior Wall EPS Decorative Lines ,Polystyrene moulding,Eps shape moulding - TD-SU12

| Place of Origin: Shanghai China (Mainland) | Brand Name: TONGDA | Model Number: TD-SU12 | Material: Polystyrene |

| Polystyrene: Frame moulding | Cement,: fibre mesh | Impact strength: J ≥6.0 | Size: custom |

| Materials: Styrofoam, Polymer-modified | Density of foam: 20-22kg/ m3 | Tensile strength: ≥ 0.2 MPa | color: cement,light yellow |

| Packaging: Plastic packing | Usage: External wall prettification |

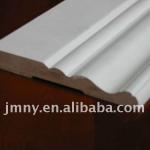

Polystyrene frame moulding

Product features Description

1.Easy for installation,low cost

2.Light weight,adpt to high building and villa

3.Environmental product

4.Waterproof

5.Easy & quick to construct, convenient design, short construct cycle

6.It can be designed in varietyies of shapes and styles

Polystyrene frame mouldingmaterial:

Styrofoam, Polymer-modified

Polystyrene frame moulding specifications:

Covered with cements,easy to construct,light in weight,shapes & styles can be freely designed.Replacement for gypsum's made mold

Advantages of the Polystyrene frame moulding:

We produce this product by CNC machine, cutting standard

Our products are light weight, it's easy for delivery and installation.

High quality, have good flexibility and tenacity, it’s difficult for cracked, deformation and have long durability.

Can be used for many application, such as windows surrounding, Cornice line

High productivity,production efficiency of EPS cutting machine is 20 times than GRC producing machine

We can manufacture products with different shape according to customers' need

Features of the Polystyrene frame moulding:

1) Energy-saving, lightweight, and environmental protection

2) Polyphenyl granule in Vanjoin board has good heat-insulation effect and heat lost ratio is far below the other brick wall building 3) Energy-saving effects of the building is greatly improved

4) Raw materials do not include harmful substances

5) Environmental products, it is highly recommended by the government

6) Capacity: 650kg/m3, just one sixth of the brick building

7) Comparison of inner wall panel 75 and 120mm it will increase 12m practical area, for 100m2 house, it will increase 4.16m2

8) Waterproof and damp resistant 9) With fireproof feature

Polystyrene frame mouldingIntroduction:

EPS decorative moulding is composed by polystyrene, self-adhesive fiberglass mesh cloth and Polymer-modified, cement .Don't be affected by changes in temperature, can be prevented from humid,heat and cold. EPS decorative moulding is a kind of succedaneum of GRC,which is environmental material. This new material owned the advantages GRC don't have.EPS is adapt to high building, especial for european style building,not only can show elegant decoration style ,but also can shorten the difference in temperature of the external wall.

The product is EPS expanded polystyrene plate cutting according to size and shape, and wipe the special mortar alkali mesh cloth to form a protective layer. It is a new type of exterior decorating line, and it is the alternative of traditional cement component (GRC).

Usage:

This kind ofPolystyrene mouldingcan be used in steel structure workshop, easy building and air clean room as walls, ceilings

Polystyrene frame moulding specification:

| Item | EPS decorative moulding | decorative component |

| Demards for constructors | Don’t need professional constructors,few numbers of constructors | Need professional constructors,many numbers of constructors |

| Installation | Convenient, Optional cutting, splicing and paste, Installation time short,no requirements for wall. | Time for a project is relatively long,difficult for cutting, have requiements for wall |

| Surface coating | Surface coating have high waterproofness,decrease the amount and cos of coating | Need grinding trimming, need to do waterproof coating processing |

| Making time | Short time ,about 10 days | Long time,about 5 days |

| Weight | Light weight, 7-8kg/m3,easy for delivery | Heavy weight,35-50kg/m3difficult for carry in high building, |

| Appearance | Smooth,blance, Little deformation, Shape diversity,high texture | Lack of homogeneity, porosity, large deformation |

| Cost | 50% deposit, and 50% balance be paid before shipping by T/T. | 50% deposit, and 50% balance be paid before shipping by T/T. |

| Production efficiency | Producing by CNC cutting machine,stable quality and quantity | Should make a mould first,low Production efficiency |

| Materials Hollowing | Materials blance,don’t hollowing | Itself is cavity |

| flexibility | elastic material, can moderate bending | Rigid material, fragile, easy fission |

| hydroscopicity | Don't suction, hydrophobic | Suction, and cavity ponding |

| Joint quality | Easy processing, rarely crack, no water seepage, interface flat | Difficult to control, joint place cracking serious, need to be waterproof processing, interface not blance |

| Working life | Surface coating owned weather resistance, Freeze-thaw resistance, toughness, not cracked | Will crack, water seepage in crack place, easy to appear the phenomenon of thermal break |

Polystyrene frame moulding

Detailed parameters:

1.Composition:

Core materials: Aluminum, Phenolic

2.Construction points:

1, You should pay attention to the EPS product protection, it is strictly prohibited heavy impact. If damaged, you should reinstall the entire EPS components

2,When pasting the EPS, the mesh should be turn and pack, or it can pasting only in the special circumstances. Press the EPS component to make the mortar flow out, and make the gap narrower than 3mm. The gap should be full and keep the EPS component surface clean.

3, An application of gray mortar joint should be flat by the knife so that EPS components into one. After drying, if the EPS component patchwork excess adhesive mortar can be left by sandpaper

4,If it need to splice, it should be assembled well in advance the size and angle measurement, and pre-assembled in the smooth place, the gap is not greater than 3mm. Bonding materials for the splicing adhesive mortar, the mortar consisitency can be little bigger. Splicing need to even squeezing and hammering to meet the requirements of the mortar joint.

5, For the bigger EPS component, it need to be temporary fixed at the installation.

6, According to the construction drawings, draw the positioning line(center line or edge)at the place to fix the EPS component.

3.Advantages:

Energy-saving

Light weight

Sound insulation

Environmental protection

Most area-saving

Most waterproof

Most fire-proof

Most sound-insulation

Best hanging force

Most anti-seismic and impact resistance

Largest span and height thin webbed wall

Most civilized, environmental, high efficiency construction.

4.Supplied to: Iran, Kazakstan, Russia, Australia, India, Dubai, South Africa and so on.

Our Service:

we can provide the service of installayion supervisin and training by extra.

Polystyrene frame moulding

Contact details:

| Contact Person: | Mr. James Zhao |

| Company Name: | Shanghai Sunnyda House Co., Ltd. |

| Country/Territory: | China (Mainland) |

| Add: | 29, Huahui Road, Songjiang District, Shanghai, China |

| Zip: | 201505 |

| Tel: | 86-21-37695697 |

| Fax: | 86-21-37695695 |

| Mobile Phones:: | +8613916952223 |

Polystyrene frame moulding

| Packaging Detail:Customer requirement |

| Delivery Detail:THREE DAYS |