construction materials lexan polycarbonate embossed sheet - JFL1556

| Type: Sun Sheets & PC Embossed Sheets | Place of Origin: Zhejiang China (Mainland) | Brand Name: JIEFENGLONG | Model Number: JFL1556 |

| COLOR: AS CUSTOMS' | ISO: 9001:2008 | DENSITY: PRODUCE ACCORDING CLIENTS' DEMAND | TEMPERATURE RESISTANCE: -40 TO +120 Celsius degree |

| LIGHT TRANSMISSION: REACH 18% -82% | IMPACT RESISTANCE: 250-300 TIMES OF THAT OF ORDINARY GLASS, 20-30 TIMES OF PMMA | SOUND INSULATION: GOOD | ANTI -FOG: GOOD |

| FIRE RETARDANT: CHINA'S NATIONAL STANDARD GB8624-97.BELONG TO B1LEVEL | INSTALL: EASY |

Construction Materials Lexan Polycarbonate Embossed Sheet

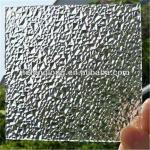

PC embossed solid sheet is made by polycarbonate resin. On the basis of common pc solid sheet’s technique and improvements of molds and production, the optical properties are changed as the surface structure of the product varies. Single side of pc embossed sheet contains UV protective layer, therefore, its mechanical properties, fire retardation, applicable temperature and chemical properties are consistent with common solid sheet. By changing the physical shape of the surface, when light gets through the embossed sheet, it produces light scattering to get a vague hazy effect. Currently, pc embossed sheet is very ideal architecture material.

Features of Product

1. Light transmission

PC embossed sheet has very good light transmission. Prolonged sun exposure of UV coated plate does not produce yellowing, fogging and poor light. The loss of light transmittance is 6% for embossed sheet and 15%-20% for PVC after ten years. As light through its convex particles produces light scattering, it has good optical effect. For more information about light transmission, please feel free to contact us.

2. Anti-UV & Heat Insulation

UV protective layer, 98% UV absorbed.

3. Light weight, high impact strength,excellent physical and mechanical properties and well bending performance

The mechanical properties of pc embossed sheet are consistent with pc solid sheet. Maintaining good impact resistance for a long time in a wide temperature range (-40 °C -120 °C).

4. Fire retardation

The sheet meets the national standard GB8624-1997 and ranks at B1 retardant material level. In the process of combustion, the sheet does not produce any smoke and toxic gases, and automatically turns off from the fire. It has good fire retardant properties.

5.Wide-ranging application, good weather-resistance

Maintaining the stability of mechanical properties between -40°C to +100°C, the sheet does not occur the cold crisp above -100 ° C and without softening below 145 °C. Small size change from 100 ° C to -40 ° C, the rate of change is ≤ 0.3%. 2000 hours of artificial aging test towards the sheet, the yellowing degree was grade 2, and the transmission rate was decreased by 0.6%.

6. Soundproof

The sheet can effectively reduce the noise, and is the best choice for soundproof.

7. Convenience for transportation and construction

Light weight, standard size, convenient transportation & construction, easy cutting and punching, cold bent and good processing performance.

8. Condensation inhibition

Under normal circumstances, when the outdoor temperature is 0°C, room temperature is 23 °C and the indoor relative humidity is below 80%, the inner surface of the material does not frost.

9. Chemical resistance

The Sheet can resist various kinds of harmful corrosive materials, such as organic acid, inorganic acid, vegetable oil, neutral salt solution, aliphatic hydrocarbon and alcohol, etc.

Specification:

| Thickness(mm) | Weight(g/m2) | MinCurvingRadius(mm) | MinSpanAccordingly(mm) | |

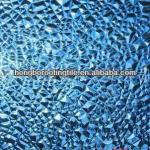

Diamond embossed sheet | 2.7 | 3 | 540 | 1080 |

| 3 | 3.36 | 600 | 1200 | |

| 5 | 5.76 | 1000 | 2000 | |

Drip embossed sheet | 2.3 | 2.45 | 460 | 920 |

| 3 | 3.29 | 600 | 1200 | |

| 5 | 5.69 | 1000 | 2000 |

Max width is 2.1m, length no limited, thickness from 2-12mm.

The min thickness of diamond embossed sheet is 2.7mm , while that of drip embossed sheet is 2.3mm .

Characteristics:

- The embossed surface reflects light, meanwhile refracts light for diffusion effect, which can weaken light pollution and get comfortable visual conditions.

- Various colors and thicknesses, thermal formable and non-sensitive to scratch

- The impact resistance of drip embossed sheet is better than that of diamond embossed sheet.

4. The surface is paved by single-face PE protective film.

Applications:

- Commercial Building Lighting

- Industrial architecture lighting

- Stadium roof and indoor play area

- Transportation infrastructure

- Residential architecture lighting

- Exterior–protected construction and curtain wall

- Bathroom and swimming pool

| Packaging Detail:both sides with PE films |

| Delivery Detail:within 7-10 days after accept the deposit |