chinese Mongolia black granite with countertop tile - GSR008

| Type: Granite | Place of Origin: China (Mainland) | Brand Name: SR | Model Number: GSR008 |

| Color: Black | Surface Finishing: Polished | Granite Density (g / m³): 2 - 3 | Stone Form: Big Slab |

| Stone Name: Golden diamond | Bottom color: Black | Vein color: Black | Style of flowers and plants: Other |

1.Place of origin:Mongolia

2.Range of application:

Indoor and outdoor decoration. Component. Stones. countertop sink

3.Range of application:

Indoor and outdoor high-grade adornment. Component, countertop, sinks

4. Specification:Thickness 2cm,96”×26”, 98”×36”, 108”×42”, 108”×52”

Can be customization, according to customer requirements

5. Properties

A).Physical property

1).Porosity/permeability:granite physical permeability is almost negligible, between 0.2% and 4%.

2).Thermostability: granite has high strength heat-resistant stability, it will not change,

Because of the change of the outside temperature, granite because of its high density and

Won’t change due to changes in temperature and the air.

3).Corrosion resistance: granite has a strong corrosion resistance, so a wide range of chemical corrosion products applied in reserve.

4).Ductility: granite extension coefficient range 4.7x10-6 - 9.0x10-6(inch x inch)

5).Color: the color of the granite and materials are highly consistent

6). Hardness:granite is the most hard building materials, also because of its superior

Hardness and make it have good wear resistance.

B)Chemical property

Granite is mainly composed of feldspar, quartz, biotite, but also is accompanied by the

Presence of other minerals

| Composition | SiO2 | AL2O3 | Cao | MgO | Fe2O3 |

| Conten(%) | 67-76 | 12-17 | 0.1-2.7 | 0.5-1.6 | 0.2-0.9 |

7.Application

Natural granite products according to different processing methods can be divided into:

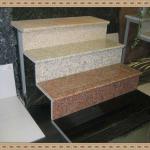

1).Axed slab

Stone surface through hand chop axes machining on the surface, have surface roughness axes strip lines with rules. Used to prevent slippery floor, stairs, pedestal, etc.

2).Planed slab

Stone material surface mechanical planning, flat surface, and there are mutually parallel plane cutting lines, similar to chop plank axes USES, but surface texture is more exquisite.

Commonly used in the ground, the steps, pedestal, step, etc.

3).Polishing slab

Stone material surface after fine grinding and polishing processing, smooth shiny surface,

The crystalline structure of the granite texture clear, color colorful, high gloss smoothing

is applied to the surface effect of wall, ground, cylinder, the ground of skating rink,

Kitchen top, sink, monument, nameplate etc.

8.Quality inspection requirements

1).The dimensions specified value or allow the deviation value

Length≤±1mm,width,thickness±1mm

2).Surface flatness specified value or allow the deviation value≤0.5mm

3).Diagonal specified value or allow the deviation value≤0.5mm

4).Gloss degree≥90°

9.Pack

1).Wooden splint pack,separate the slabs with diaphanous gluey thin film

2).Wooden case packing, between slab and slab, according to the requirements ,separate the slab with diaphanous gluey thin film or foam film,reinforce the fumigate wooden case with iron bar

3).Foam packing

10.technological process

There are four main kinds granite slab production line:

Specifications slab production line, sheet production line, rough surface decorative slab

Production line, irregular slab production line

If need detailed information, PLS don't hesitate to contact me!

| Packaging Detail:slabs mainly by wrapping them in plastic packing, and then with a wooden clip, each about 15 pieces . After such as open cut finished product, usually packed in wooden cases and bubble |

| Delivery Detail:25-45days |