2014 warehouse structural design - order

| Place of Origin: China (Mainland) | Brand Name: jingta | Model Number: order | Standard: GB 50205-2001 |

| Manufacturing Technology: Drilling, Cutting, Assemblaging, Welding, Rectification, Testing etc. | Surface modification: Ball Blasting, Painting, Hot-dip Galvanizing | Type: Workshop, Warehouse, Prefabricated house, Nonstandard Component | Welding Technology: SAW, Carbon Dioxide Arc Welding |

| Welding Testing: Ultrasonic Testing, X-ray Testing | Ways of Supply: Order | Weight Measurement: Theoretical Weight | Shipment: Bulk Cargo or Container |

| Validity of Prices: 15 Days |

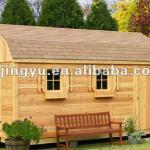

2014 warehouse structural design

Structural steelis steel construction material, a profile, formed with a specific shape or cross section and certain standards of chemical composition and mechanical properties. Structural steel shape, size, composition, strength, storage, etc., is regulated in most industrialized countries.

For a whole set of industrial steel projects, it usually includes following parts:

Steel frame: Column and beam (H-section), roof&wall purlin, bracing ect.

Conection Parts: High strength bolts, common bolts, nut ect.

Wall&Roof: EPS,Rockwool,PU sandwichpanel, Corrugated steel sheet with fiber glasswool

Door: Rolled up door or Sliding door (sandwich panel)

Window: Plastic steel or Aluminum alloy window

Surface treatment: Hot dip galvanized or painted.(all colours we can do)

Crane(if necessary): 5T,10T,15T,ect. space frame truss

Featured products:

Steel structure workshop/industrial plant

Steel structure warehouse

Steel pergolas

Sports center

Steel sheds

Non-standard components fabrication

According to the supplied technology parameters by customers (for instance: wind speed, rainfall, snow load, earthquake etc.), we can provide the design service. More specific parameter contents can be gotten from the Steel structure preliminary design parameter table

Quality control

Materials must enter factory along with Mill Test Certification, invoice, physics test report. After entry, there will be a double check from skilled workers. Only materials which pass the checking can be accepted. Rejects will not be allowed to entering factory.

Quality standard of steel structure components:

1. Material preparing. Cutting sheets has no crack, dust, layered, default above 1mm.

2. Cutting precision. Roughness, uneven level, melting should be according with regulation.

3. Drilling. Well shaped, and without burr.

4. Objection of welds. The objections of welds must be not deadly welds.

5. Welding dreg. Welding dreg must be cleaned out and surface objections must be solved according to regulation.

6. Frame appearance. There must be no distortion and there is no scar, smear and etc in frame surface.

7. High-strength bolt surface. There must be no ferric oxide, burr, scar, wrong smear, etc in the surface.

8. Marks. Marks must be complete, centre, precision position and fresh color.

9. Painting objections. There is no cast, defaults and skip.

10. Painting appearance. The painting must be equal, and there is no discrepancy in color, no wrinkle in surface. The alterative paint coat due to cutting, welding or firing must be solved. The coating is no less than 120μm.

Jingta Building Co., Ltd. is a qualified construction company which has the steel structure special design Grade A level and national steel structure professional contract. We have got a certificate of ISO9001:2000 quality management system in 2001 which is one of the large steel structure companies in Shandong.Our company is mainly doing the design, fabrication, assembling of steel structure projects. Our products have widely used in the business line of light steel structure warehouse, heavy industrial workshop, exhibition hall, gymnasium, supermarket, office building ect. Products are exporting to many countries all over the world such as Australia, Belgium, Cyprus, Demark, Mali, Chile, UAE ect.

Parts of case:

| NO. | Content of project | Contract scale | Project location | Order date |

| 1 | Cow Mill Project | 144M x 33.5M | New Zealand | 2010 |

| 2 | Workshop item of Alcohol mill | 2720 m2 | Mali | 2009 |

| 3 | Electricity board project s | 203.775T | Cyprus | 2008 |

| 4. | Roofing steel structure i | 65.96T | Australia | 2010 |

| 5 | Steel beam | 66.217 | Australia | 2010 |

| 6 | Steel pergolas | 35.432T | Australia | 2009 |

| 7 | Arc roof steel members | 203.775T | Cyprus | 2008 |

| 8 | Shopping mall | 416t | Belgium | 2008 |

| 9 | Workshop of Vass mines | 10’027 m2 | India | 2008 |

| 10 | Wleded T bars | 100.461T | Australia | 2011 |

Cerficates:

1. What kind of service do you supply?

We are a professional steel structure manufacture; we can design and fabricate as per your requirement

2. What information should I provide for a whole set of project quotation:

To offer the accuracy quotation, please let us know the detail parameter including Length*Width*Height,wind load, snow load, earthquake intensity ect. It could be better If you have drawings on hand which we can quote according to

3. What should I do if I don’t have drawings?

It doesn’t matter, we can make drawings or suggestions to you, but you should let us know the design parameters (refer to question 2)

4. Do you also supply installation service?

Re the installation, you will cost too much if we install in your local place. But we can send engineers to supervise it. Of course, it is the best way if you can send your local engineers to China; we can train them how to install the project.

5. What is the material grade?

It can be Q235, Q345 or other standard as per your requirements

| Packaging Detail:export packing in bundles. |

| Delivery Detail:usually 45--60 days after order |