1mm-12mm hard coated polycarbonate anti scratch sheet - GWX-S100

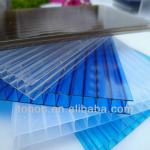

| Type: Sun Sheets & PC Embossed Sheets,polycarbonate sheet | Place of Origin: Guangdong China (Mainland) | Brand Name: GWX | Model Number: GWX-S100 |

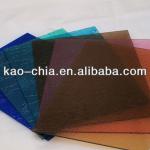

| Material: 100% virgin bayer material | Size: can be customized | Color: transparent,blue,green,opal.brown | Packaging: Protective PE film on both side |

| UV: UV coated | Quality: 10 years warranty | CE: ISO9001:2008,SGS,CAS |

Specificatons

| Thickness: | 1.5mm-12mm |

| Length : | 2.56m |

| Width: | 1220mm |

| Color | Transparent, Green, Blue, Brown, Opal. |

| Warranty: | 10 years quality guarantee |

| Certificate: | ISO9001:2008,SGS,CAS |

Note: special specifications can be customized.

Hard coated anti scratch polycarbonate sheet for construction materials , windows

Features

1. Light transmission:

Fine light transmitting rate approve to 30— 85%.

2.Weather resistance:

With anti-UV inhibition on the surface, it can prevent the resin from fatigue and yellowing caused by UV. The anti-UV agent on the surface can change the UV absorbed by chemical bond into visible light, and finely stabilize the photosynthesis of plants.

3.Impact resistance:

With the strength 250 times than the ordinary glass, 30 times than the PMMA sheet, it has less risk of breakage

4.Fire retardant:

Fire retardant is up to B2 level (based on National GB8625-88 testing, without flame or toxic gas).

5.Temperature toleration:

Without deformation within the temperature range from-40°C to +120°C.

6.Sound insulation:

It is the best transparent materials for sound insulation engineering as expressways, factories, etc.

7.Portability:

Easy for handling and drilling, won't be breakage when cutting, simple and easy be treated in using.

Technical data

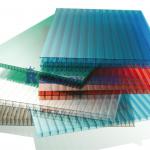

| Characteristics | Unit | Data of PC hollow sheet |

| Light transmission | % | 40 ~ 82 |

| Impact strength | J/m | 2.1 ~ 2.3 |

| Coefficient of thermal expansion | mm/m °C | 0.065 |

| Heat conductivity | W/m2 °C | 3.0 ~ 3.9 |

| Service temperature | °C | -40°C~+120°C |

| Tensile strength | n/mm2 | ≥60 |

| Bending strength | n/mm2 | 100 |

| Bending elastic modulus | mpa | 2400 |

| Tensile stress at break | mpa | ≥65 |

| Elongation at break | % | ≥100 |

Applications

1)roofingfor swimming pool, shopping malls, commercial streets

2)Sunshadefor stadiums and bus stops, gazebo, open air carport

2)lighting canopyfor corridors, passages and subway entries

3)ATM machine covers, telephone booth, gateways, garages

4)Sound and heat insulation wallfor expressways and houses

5)Instead of glass, decoration door, curtain wall

6)Soundproof materialfor partitions

7)Unbreakable materialfor glazing widows, roof glazing.

8)Lightingof modern villa, rain-proof lighting shed of underground garage entryway

9)Front wind shieldsof motorcycles, airplanes, trains, liners, vehicles, motorboats, submarines and riot shields

Package

Accessories

Installation instructions

1.PC sheet do not contact the surface of cement walls.

2.Clean the frame so as to keep smooth of notch.

3.Use the appropriate sheet thickness which allow enough curvature radius.

4.Allow enough space for the expansion of panel. At least 30 mm distance between screw hole and the panel's edge.

5.Use the neutral silicone,don't use PVC stripes.

6.Use the dynamoelectric cutting tool,(Tungsten carbide blade). please make sure the panel is stable to avoid its shaking.Forbid tear away the film on the surface before cutting.

CLEANING & MAINTENANCE

According to correct procedure, suitable cleanser and tools are used to clean the sheets regularly. It could keep the sheets graceful and extend the sheets’ useful life:

1. Rinse sheet with lukewarm water (under 60°C)

2. Please choose cleanly and soft cloth or sponge with neutral liquid soap or detergent to clean the dirt on the surface lightly

3. Rinse sheet once again

4. The soft cloth with anhydrous alcohol could be used for cleaning, if oil, wet paint, glue spotting and other things are on the sheet..

5. Rinse with cold water and dry with a soft cloth to prevent water spotting after cleaning.

Recommendation of using solvent for cleaning

Absolute alcohol, Petroleum ether, Hexane

NOTICE

Steel wool, brushes and other crude material are not allowed to contact with the PC sheet.

Do not use drawknife, razor and other edgy tools to scratch PC hollow sheet.

More about us

| Packaging Detail:Protective PE film on both sides |

| Delivery Detail:Within 10 days |