1220*2440mm standard size blockboard laminated blockboard - TR-Block00100

| Type: Laminated Wood Boards / Blockboards | Place of Origin: Shandong China (Mainland) | Brand Name: T&R | Model Number: TR-Block00100 |

| Surface Finishing: Double-Sided Sanding | Grade: First-Class | Layers: 3-Layer | Surface Material: Bintangor |

| Core Material: Poplar | Formaldehyde Emission Standards: E0 | Board Core Structure: Hollow | Size: 1220*2440mm |

| Thickness: 12-30mm | Material: poplar | Glue: E0,E1,E2 | Core: Poplar,Pine,Paulownia wood,Fir,Birch |

| F/B: Okoume,Maple,Walnut,Oak,Ash,Brich | Density: 380-450kg/m3 | MOQ: 1*20'GP | Usage: furniture,door,book shelves,wall panels to benches |

| Delivery time: 14days after deposit |

1220*2440mm standard size blockboard laminated blockboard

| Blockboard property | Measurement unit | Approximate Values |

| Density | kg/m3 | 600 to 625 kg/m3 |

| Nail holding strength | kg | 70 to 100 kgs. |

| Screw holding strength | kg | 200 to 225 kgs |

| Moisture Content | measured in % | 8 to 10% |

| Modulus of Elasticity | N/mm2 | 5000 to 6000 |

| Modulus of Rupture | N/mm2 | 50 to 60 |

Sources of Blockboards

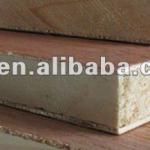

----Blockboard is made up of a core of softwood strips. These strips may be up to about 25mm wide. The strips are placed edge to edge and sandwiched between veneers of hardwood. The sandwich is then glued under high pressure.

Types of Blockboards

Based on their quality and suitability of use, the two main types of blockboards are:

1. Interior Grade:

Suitable for indoor use, such as for furniture used inside the home or for doors.

These types are also called MR grade (Moisture Resistant) blockboard.

2. Exterior Grade:

This type of blockboard is suitable for outdoor use and it also known as BWP or BWR grade blockboard. BWP stands for Boiling Water Proof and BWR stands for Boiling Water Resistant. Superior quality adhesives are used in making these exterior grade blockboards compared to the MR grade ones, so that the sheets can have better resistance to water.

Classification based on the wood used for the blockboard core

1 Softwood:

At their core, blockboard sheets are made up of solid blocks of wood (also called strips or battens). These solid wood blocks are placed adjacent to each other lengthwise across the board and then the front and back surfaces of the board are covered with hardwood veneers. (usually a single sheet of 4 mm ply on each side). These core blocks are almost always made from softwood obtained from softwood trees (e.g. Pine wood is very popular in India).

2 Hardwood:

While softwood core is the most common, some manufacturers do manufacture blockboards that have a core made from hardwood strips as well as hardwood veneers on the outside. Such types of boards are classified as hardwood core blockboards, and they are denser, heavier, stronger and also generally costlier.

Properties of Blockboards

- These boards have good dimensional stability (even when exposed to humidity), and exhibit high resistance to warping or twisting.

- Also have a better ability to hold nails and screws, compared to other engineered boards such as particle boards or MDF (medium density fibre boards).

- Another important characteristic of blockboard is that it is light in weight, because the core blocks that form the bulk of the board are of softwood that has much lesser density and weight compared to hardwood. Because of having low weight it is easier to transport.

- Can be finished using paints, varnishes or can be laminated. With proper finishing such as by glueing laminates on its surfaces, blockboards can be made to appear exactly like their costlier counterparts viz. plywood

- Another feature of blockboards is that they can are also easy to work with for carpenters using their regular wood working tools. In contrast, carpenters find it very difficult to work with other engineered boards such as MDF or Particle boards as these types do not hold nails and only screws have to be used.

- These boards are made in MR-Moisture resistant grade, as well as BWP-Boiling water proof grade, for interior and exterior use respectively. The BWP variety uses superior glue (phenol formaldehyde), and is stronger with better resistance to water or humidity.

Usage of Blockboards

Though most people are not aware of it, blockboard furniture is used by many people in their day to day lives. From doors to bookshelves and from wall panels to benches, blockboard is everywhere. It is cheaper than plywood or quality solid wood and its unique composition also makes it suitable for several furniture applications, where other types of engineered boards (such as plywood sheets) would fall short.

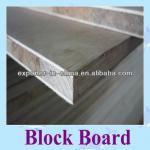

Pictures show

Contact us

Heze TongRui Building Material Co.,Ltd specializes in manufacture and export of building materials,construction materials and house decoration products. The key of our success is "TO BE AN HONESTEST SUPPLIER"Sincerely hope to cooperate with your esteemed company.

If any questiones,pls feel free to contact us~~

Many thanks~~

| Packaging Detail:Standard Export Packing for Blockboards |

| Delivery Detail:14 days after deposit(30% T/T) for Blockboards |